Agromark improves return on investment and reduces its carbon footprint with foldable bin from Tosca

In this case study, a foldable bin makes an innovative reusable packaging solution from Tosca that preserves broccoli quality while reducing reverse logistics of Spanish export specialist.

Agromark, a Spanish export company that produces and sells fruits and vegetables, needed containers to transport its fresh produce efficiently while always ensuring product quality preservation. These requirements were especially crucial for Agromark’s broccoli exports from Spain to the UK, as this cruciferous vegetable is very delicate. The Spanish export company turned to Tosca for a solution.

Tosca, a global leader in reusable packaging and pooling solutions for food supply chains, carefully reviewed Agromark’s operation model. During its consultancy, Tosca identified a solution that checked all the boxes for Agromark. The most effective way to improve efficiency and keep the broccoli at its optimal stage was to change the rigid plastic boxes that the company used. As no existing product could address all issues, Tosca offered to develop a reusable foldable plastic bin.

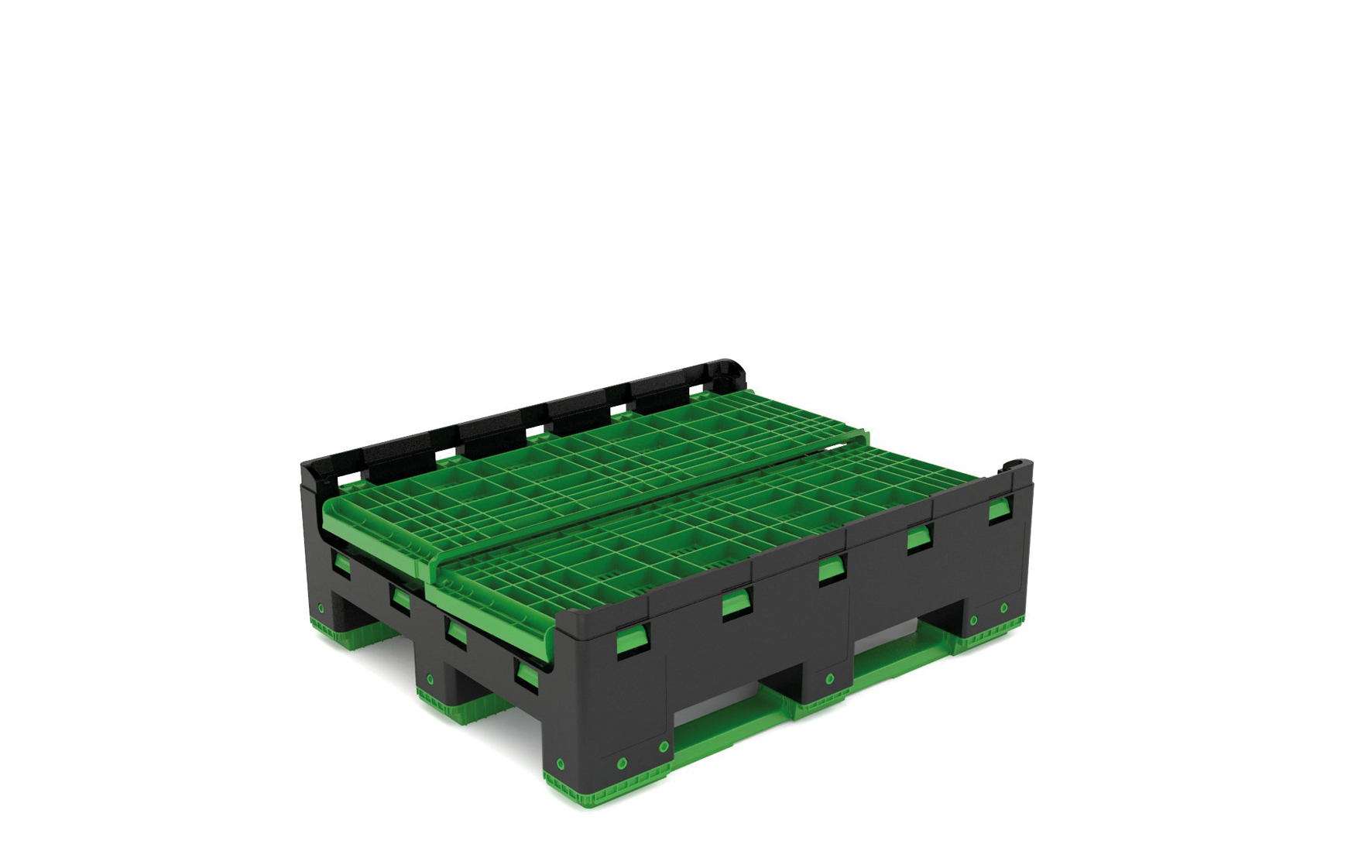

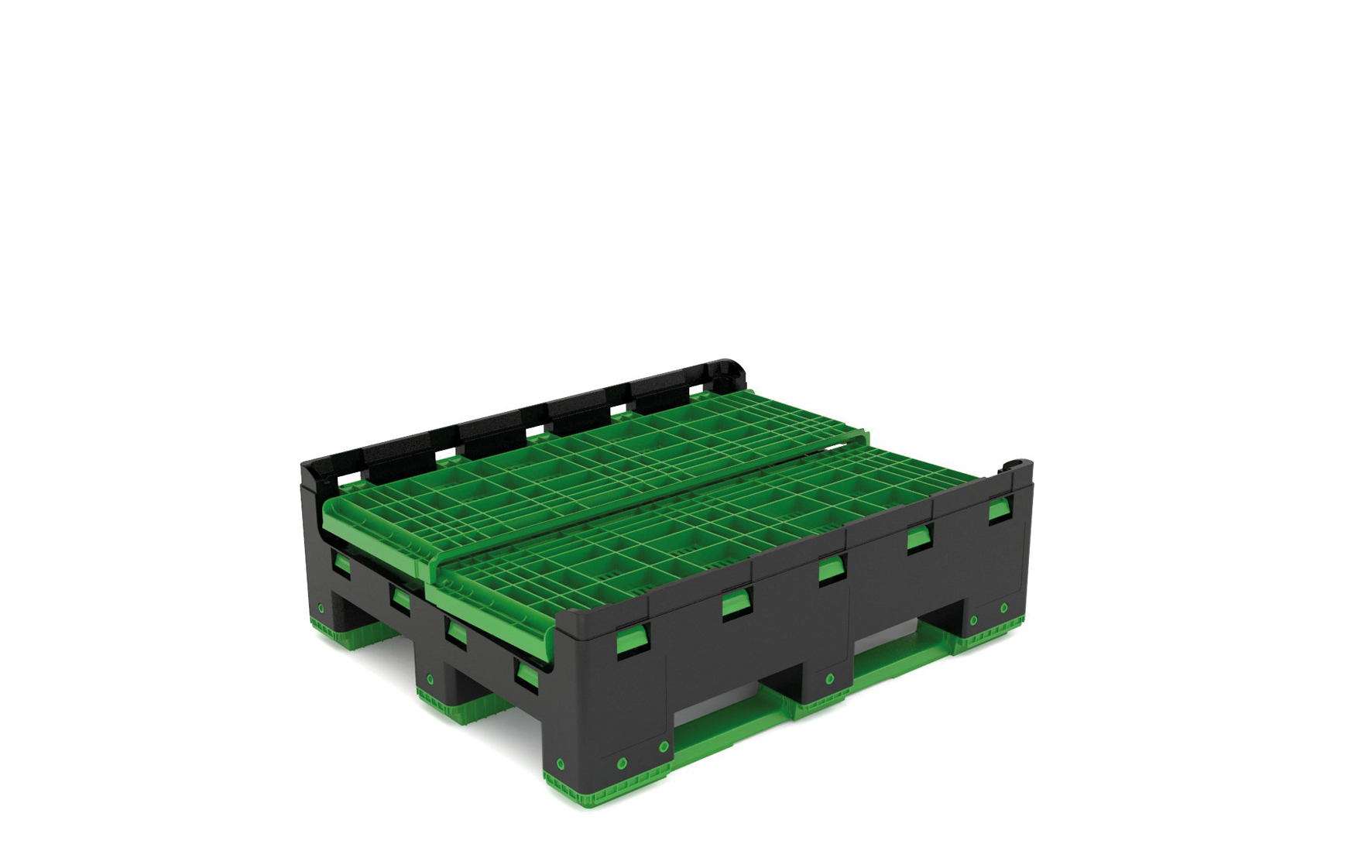

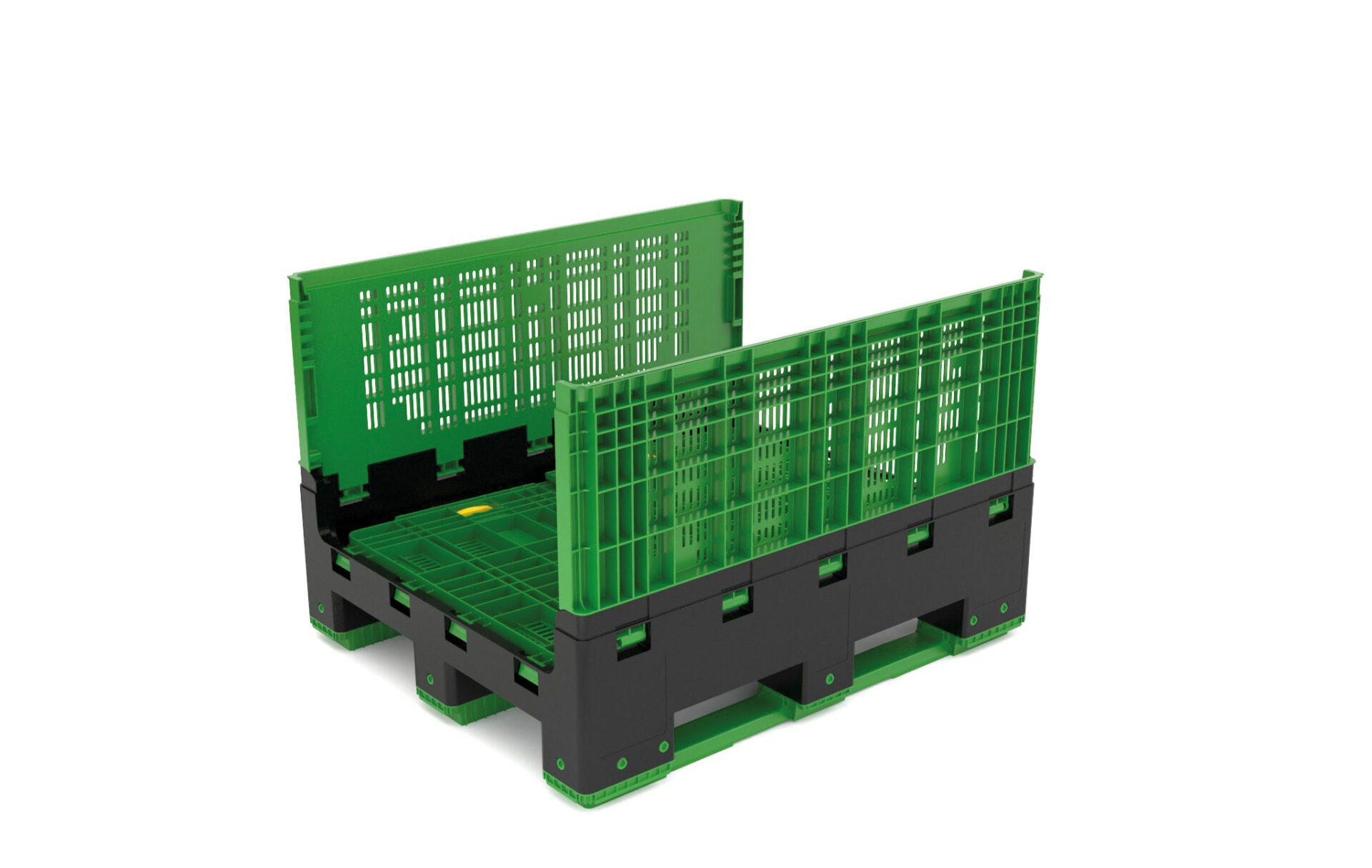

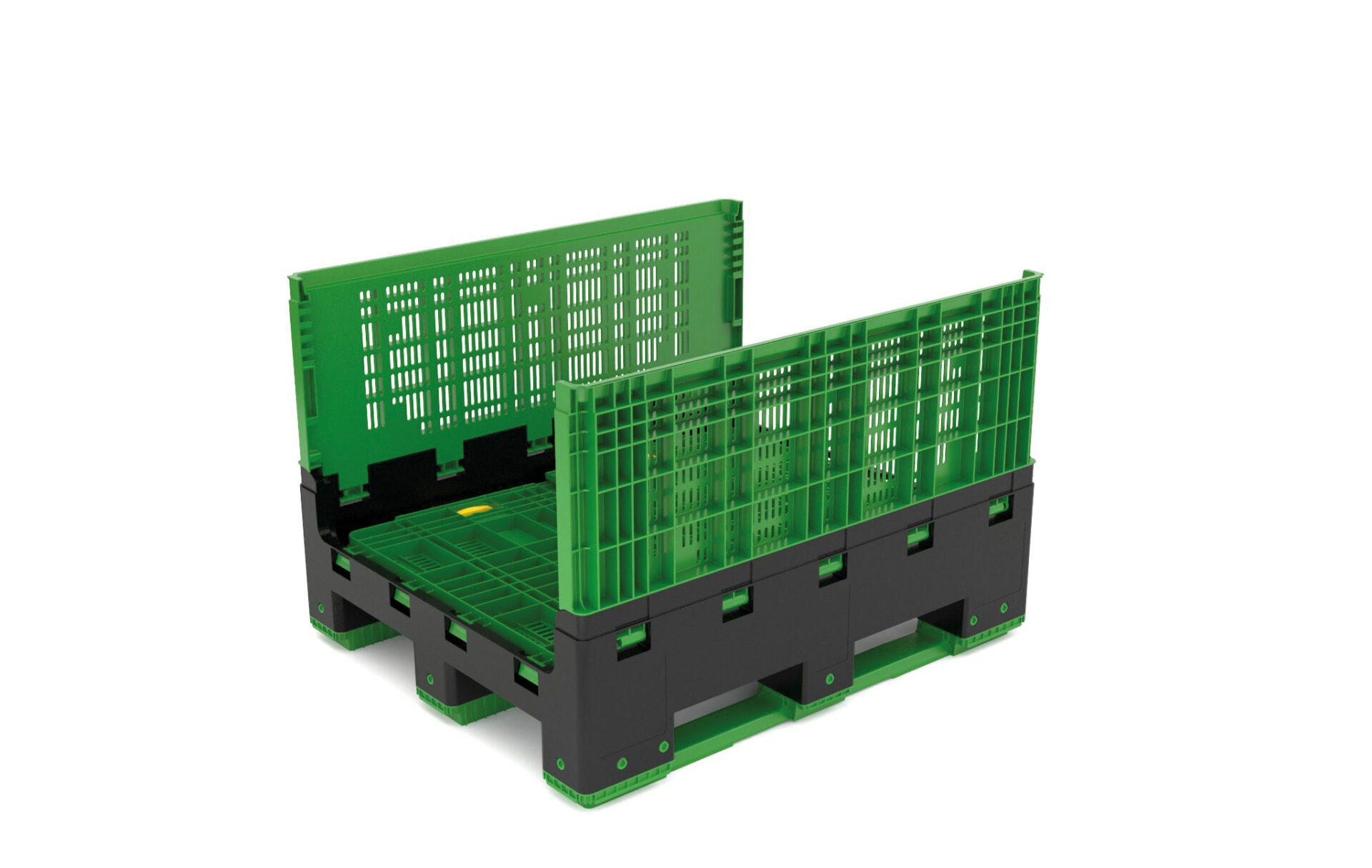

This foldable plastic container measures 120x100x80cm and comes with a base that is manufactured to the specific needs of the broccoli to protect the quality and freshness. Even when the foldable bin is filled at its highest, the container on top does not damage the broccoli. This solution from Tosca offers outstanding ventilation, ensuring Agromark’s broccoli remains fresh for longer and reaches British customers. As a result, Agromark has seen a reduction in product waste and losses.

With the advantage of Tosca’s foldable bins, Agromark was able to reduce return trips by 75%. Every 28 weeks, Agromark used to send a total of 56 trucks on return journeys. Now, with the improved efficiency of foldable bins, the grower only completes 14 return trips in the same amount of time. By eliminating 42 return trips every 28 weeks, Agromark has generated significant savings while also reducing its CO2 transport emissions.

The foldable bin from Tosca measures 80cm when filled, which is the same as the previous solution Agromark was using. However, when it is empty, Tosca’s bin can be folded, reducing its size to 36.5cm. This is crucial when Agromark takes back its empty assets as Tosca’s solution allows for a total of 182 foldable bins per truck. In other words, this foldable bin solution enables Agromark to transport 104 more empty bins per truck than when they used a rigid bin.

![]()

Carlos Doménech, Operations Manager at Agromark, said:

“We are very pleased to work with Tosca since 2015 because of their expertise on the fruit and vegetables supply chain. When we have any challenges to overcome in our business, we turn to Tosca. Their team works with us to understand our needs and recommend us the right solution that meets our requirements and makes our supply chain more efficient and future proof.”

Stackable and foldable bins from Tosca maximize transport and storage space while increasing product visibility and sales. From transport to retail floor, these versatile bins are the perfect solution for improved efficiency.

A system of pooled bins owned and managed by Tosca ensures each individual asset is utilized fully and kept in the best condition. Every customer benefits from a high-quality asset that arrives on

time, has a lower carbon footprint due to shorter transportation routes, and more efficient return logistics.