The smarter choice for liquid bulk tansport

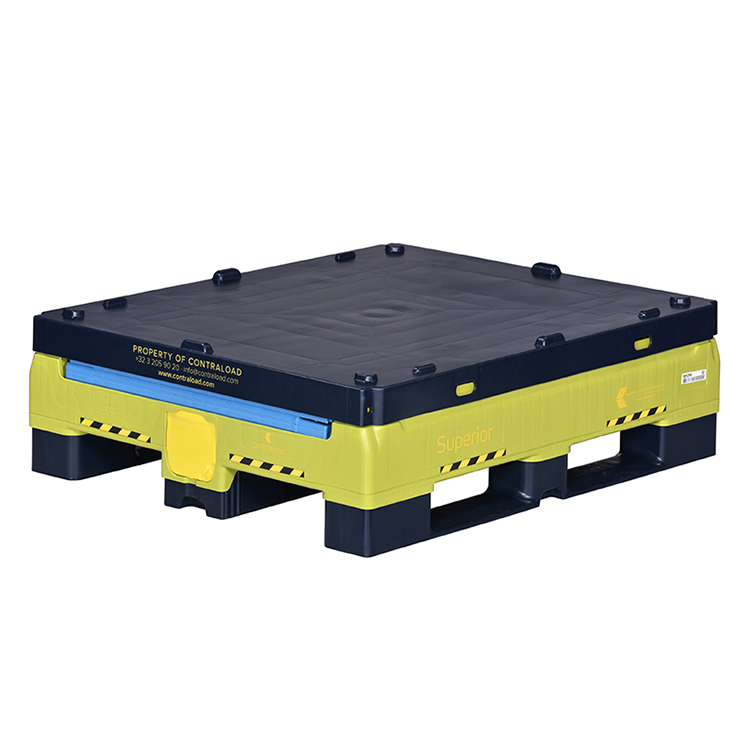

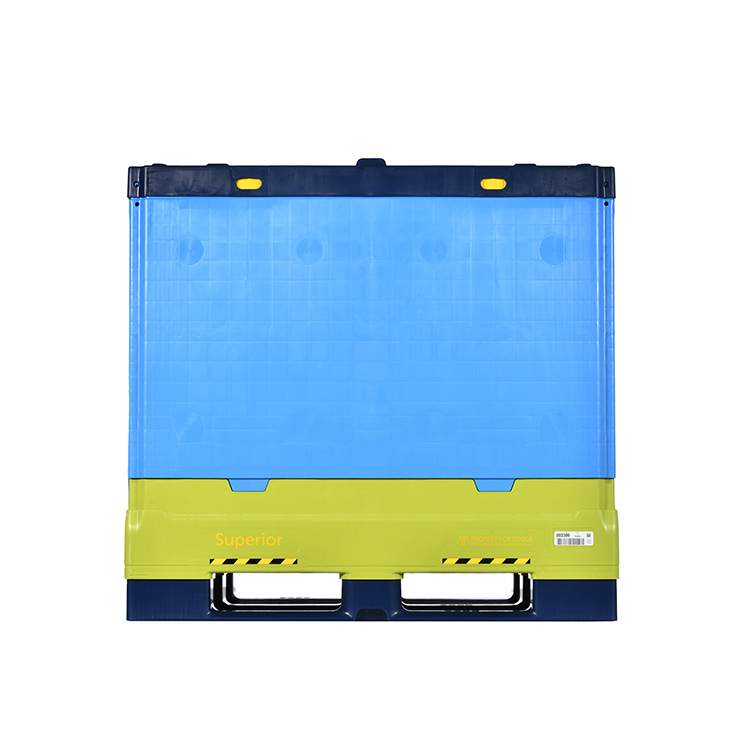

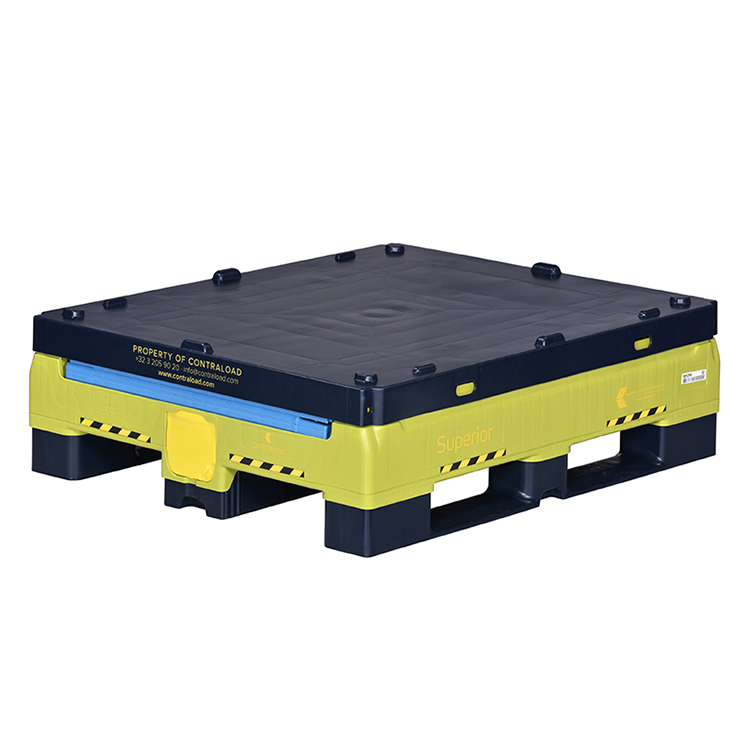

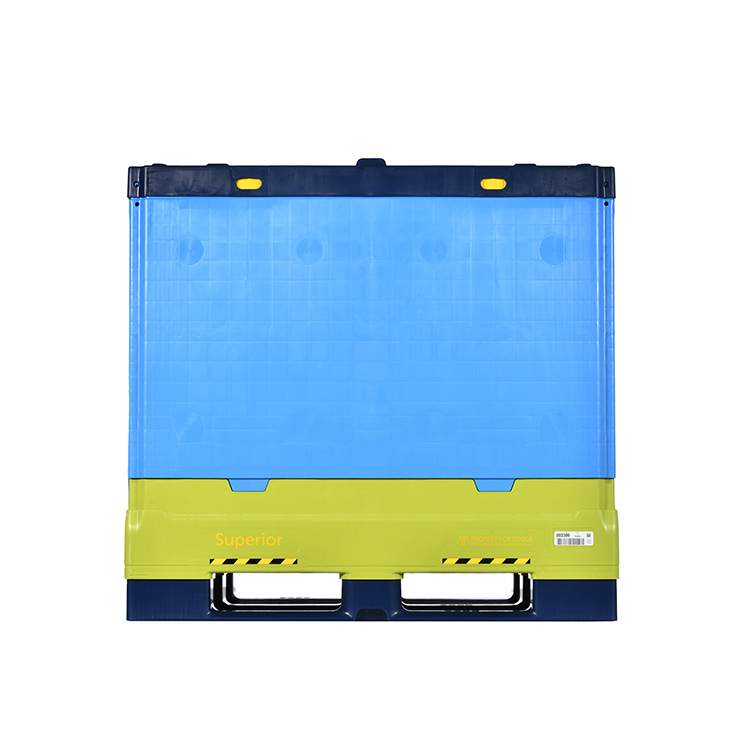

Superior Hybrid

Description

The Superior Hybrid is a food-grade foldable 1000-liter container ideal for low- and high-viscosity liquid products. It features 5 different sealable exit and entry points, and once the container is sealed, the product inside is impossible to access. The container also features a drop door, 3 runners for easy handling, and a bottom discharge to minimize residual product. Additionally, its high folding ratio saves space in storage and transit, resulting in reduced costs and a smaller carbon footprint.

Product specs

Dimensions

Loading & Stacking

Superior Hybrid

Save transportation costs

Reduce waste

Ensure cleanliness and hygiene

Save labour costs with reduced handling time

Simplify Sustainability

Comparisons - Superior Hybrid vs Stainless Steel Container