Reusable plastic packaging: The key to sustainable solutions in the cosmetics industry supply chain

Published by Tosca, under Sustainability

In this article

The cosmetics industry, renowned for its innovation and commitment to quality, is under growing pressure to reduce its environmental impact. Consumers and regulatory bodies alike are demanding more sustainable solutions, prompting brands to rethink their packaging strategies. While much attention has been given to primary packaging—the bottles, jars, and tubes that hold products—there’s also a significant opportunity to improve sustainability in secondary and tertiary packaging used throughout the cosmetics supply chain.

Reusable plastic packaging presents a powerful solution—minimising waste, cutting costs, and improving efficiency across logistics and production. By incorporating reusable Intermediate Bulk Containers (IBCs) and other returnable packaging solutions, cosmetics manufacturers can enhance sustainability while maintaining operational excellence.

Why reusable plastic packaging?

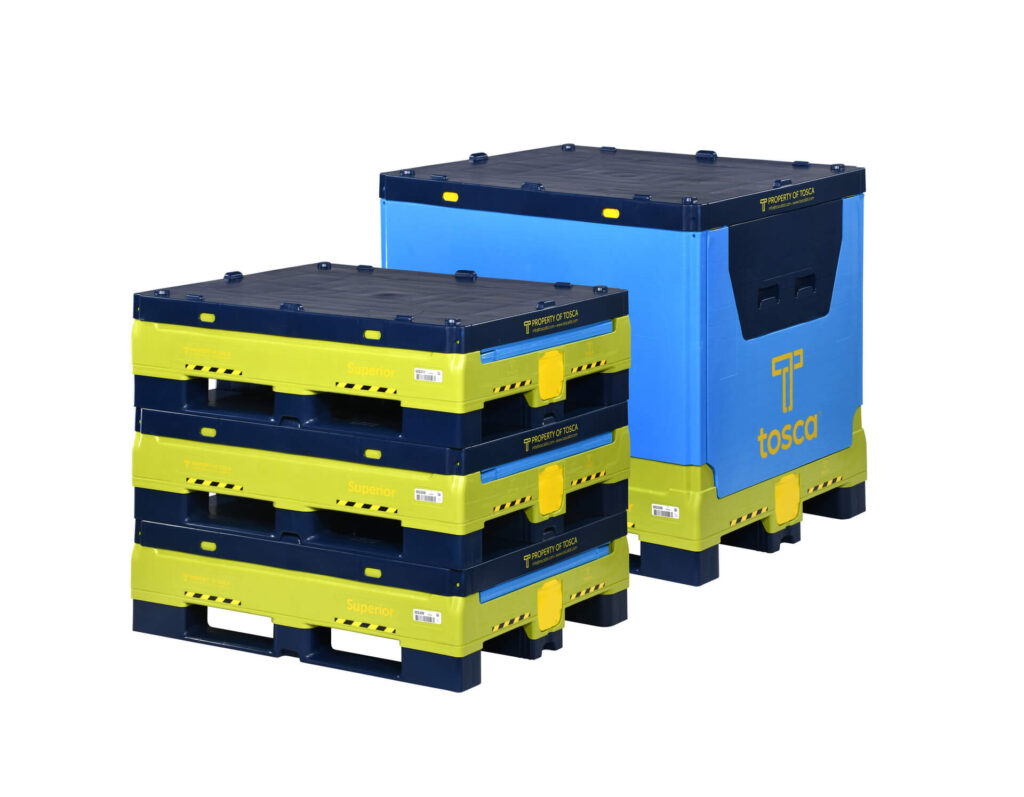

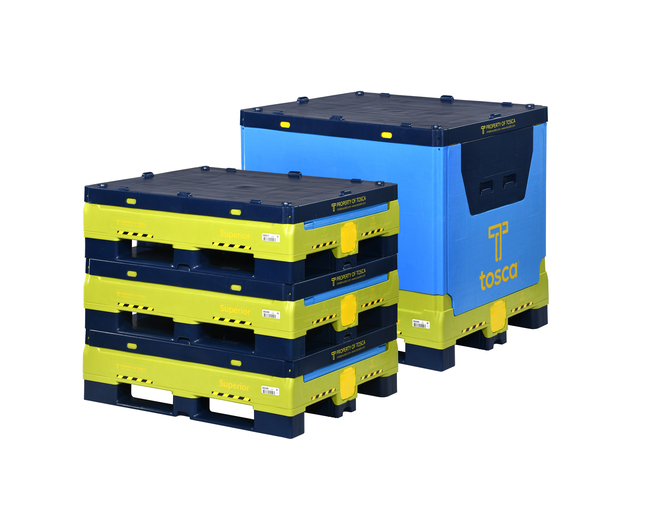

Reusable secondary plastic packaging can play a crucial role in the cosmetics industry, offering a sustainable and efficient way to store and transport products. These solutions are particularly well-suited to liquid formulations such as creams, serums, and gels. IBCs, such as Tosca’s Superior Hybrid, are designed to meet strict hygiene standards while optimising handling and transport logistics.

Key benefits of reusable packaging in the cosmetic industry:

1. Lower Costs and Less Waste

Switching from single-use to reusable packaging significantly reduces material waste and disposal costs. The squeeze system, used with Tosca’s Superior Hybrid IBC, ensures maximum product recovery—an essential advantage for high-value cosmetics. This advanced system minimises residue left in containers, improving product utilisation and cost efficiency.

Traditional single-use drums or rigid containers often leave behind substantial product waste. In contrast, foldable IBCs with liner technology enable near-complete product evacuation, leaving less than 1 kg of residue—delivering substantial savings on costly ingredients.

2. Space efficiency

Storage space is a valuable asset in manufacturing facilities. Reusable, foldable plastic packaging solutions such as Tosca’s Superior Hybrid offer a 7:1 folding ratio compared to rigid alternatives. When not in use, these containers take up far less space, improving warehouse efficiency and reducing storage costs.

This is especially beneficial for businesses working with co-packers or third-party logistics providers, where space optimisation directly impacts overall supply chain performance.

3. Hygiene and compliance in cosmetic supply chains

The cosmetics industry must meet strict hygiene standards to prevent contamination. Reusable plastic packaging, combined with liner systems, reduces the need for extensive cleaning while maintaining absolute hygiene integrity.

Liners act as a protective barrier between the container and the product, ensuring each use starts with a clean, uncontaminated surface. This closed-loop approach aligns with Good Manufacturing Practices (GMP) and regulatory requirements while also reducing water and chemical usage from traditional cleaning processes.

4. Versatility for various applications

Reusable plastic packaging solutions offer flexibility for in-house production, storage, and use with co-packers handling retail packaging. These containers are suitable for a wide range of formulations, including liquids, gels, pastes, and powders—providing adaptable solutions across production and logistics.

Smart technology for smarter reusable packaging

Technology is increasingly enhancing the efficiency and sustainability of reusable packaging. With Tosca Asset IQ, IoT-enabled IBCs allow manufacturers to track container locations, monitor usage patterns, and assess container conditions in real time.

Some cosmetics companies already use IoT sensors on rental IBCs to manage inventory levels and avoid shortages or overstocking. This level of visibility enables data-driven decisions that improve supply chain efficiency and reduce waste—supporting both sustainability and cost goals.

Predictive analytics also helps businesses anticipate maintenance or replacements, reducing downtime and ensuring smooth operations.

Rental vs. pooling: Finding the right model

Choosing between a rental or pooling model depends on your specific supply chain setup. Rental is often used in cosmetics supply chains, but pooling can also drive significant advantages.

- Rental model: Ideal for in-house operations, offering flexibility in container availability and usage. It allows companies to scale up or down without large capital investments.

- Pooling model: Particularly suited for external logistics networks, enabling shared use of packaging across a broader supply chain. Reusable assets cleaned, maintained, and distributed effectively to always meet demand.

Both models enhance efficiency, and rental contracts often include services such as regular collection, cleaning, inspection, and repairs. When used with co-packers, pooling optimises logistics and reduces costs.

A sustainable future for cosmetics packaging

The cosmetics industry has a unique opportunity to lead the way in reusable packaging solutions for secondary and tertiary supply chain needs. By embracing innovations like foldable IBCs, smart tracking technology, and flexible rental or pooling models, brands can boost operational performance while meeting sustainability targets.

Adopting collaborative supply chain models—where packaging is shared, maintained, and optimised—also fosters stronger partnerships and industry innovation. As demand for greener supply chains grows, reusable plastic packaging offers a practical path to reducing environmental impact while delivering efficiency and cost benefits.

PPWR Compliance: What is the PPWR?

Reusable packaging is a key way for cosmetics companies to stay compliant with the new Packaging and Packaging Waste Regulation (PPWR), which came into force on 11 February 2025 as part of the European Green Deal. The regulation introduces stricter rules to reduce excess packaging, promote reuse, and increase recycling across the EU. For the first time, reuse is prioritised alongside recycling, driving the shift toward a circular economy. Reusable secondary packaging helps cosmetics businesses meet these evolving requirements while reducing waste and supporting long-term sustainability goals.

To wrap up

In today’s fast-changing regulatory landscape and sustainability-driven market, reusable plastic packaging offers a smart, future-ready solution. From reducing waste and costs to meeting PPWR compliance and enhancing supply chain performance, the benefits are clear. By making the switch now, cosmetics brands can lead the way in sustainable innovation—delivering value for their business, their customers, and the planet.