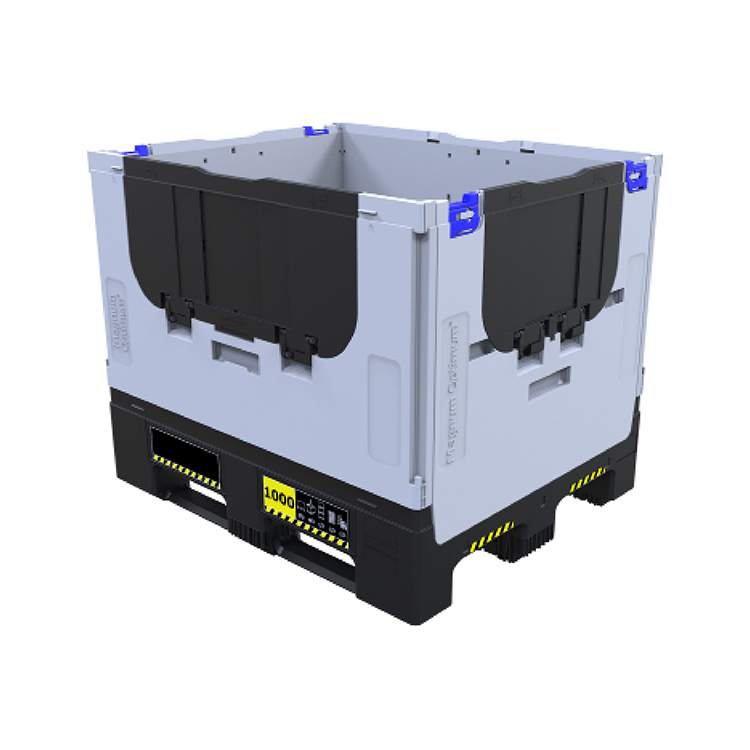

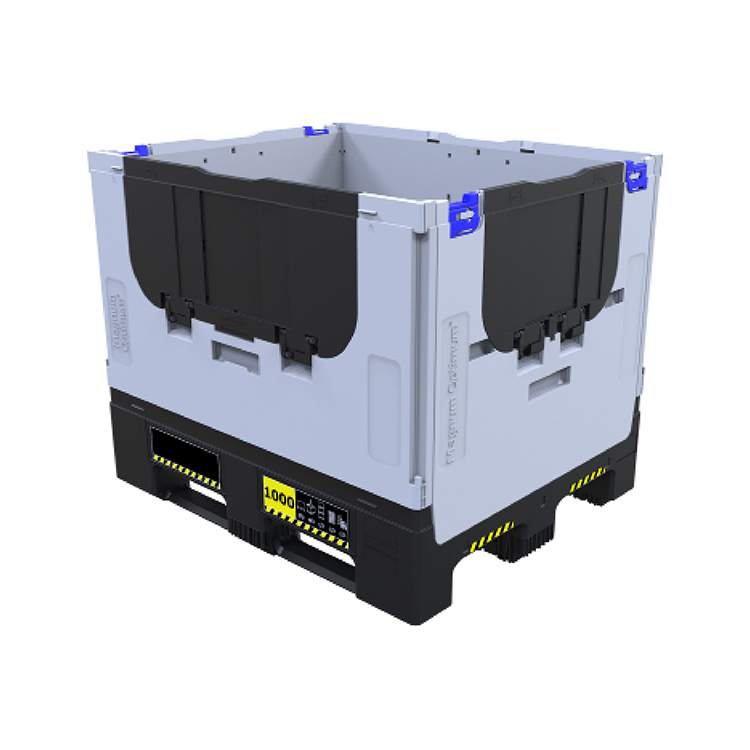

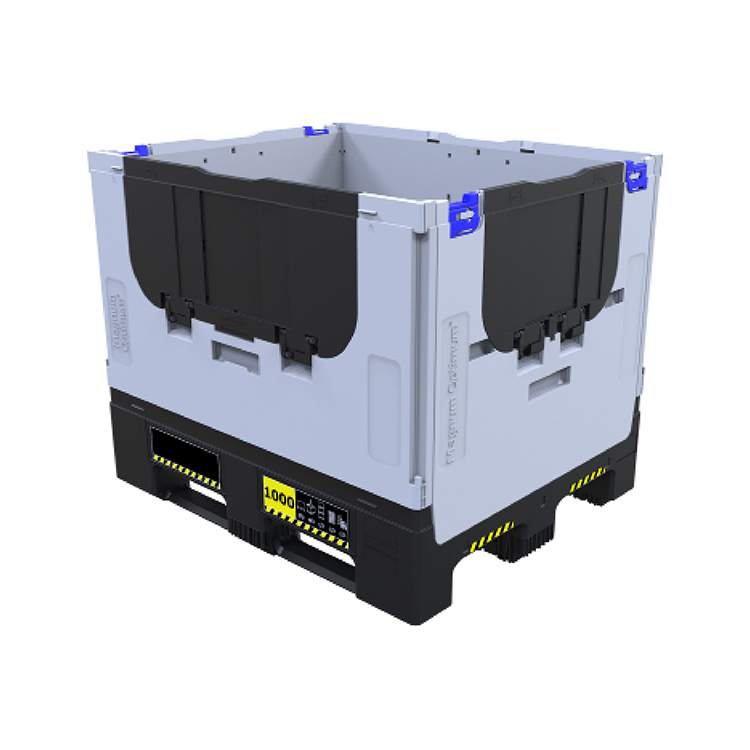

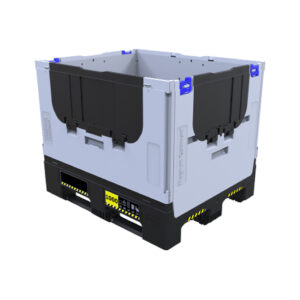

Magnum Optimum 1210

The smarter choice for bulk transport

Featuring smooth walls that are deal for dry bulk food or non-food, this foodgrade virgin PP heavy duty Folding Large Container (FLC) saves space in your warehouse and during return transport, ultimately resulting in lower costs and a reduced carbon footprint. Its durable structure and two runners ensure strength and stability throughout the supply chain, even when the container is open or folded. Designed for safe and easy handling while folding and unfolding, an ergonomic dropdoor on the long side of the container allows for easy picking.

Product Details & Benefits

Maximise Space Efficiency

Our foldable, stackable, design maximises space in your warehouse and in return transport, significantly reducing storage and transportation costs.

Maintain product quality

Constructed from food-grade virgin HDPE with smooth sidewalls, the Magnum Optimum 1210 ensures durability and stability throughout the supply chain, maintaining integrity even when open or folded.

Reliable Versatility

Ideal for dry bulk food and non-food items, the Magnum Optimum 1210’s robust design and two runners provide versatile use across various industries.

Easy Handling For Better Productivity

The ergonomic dropdoor on the long side provides easy access, and the simple unfolding/folding mechanisms make picking operations efficient and more cost-effective.

Simplify Sustainability

Our Magnum Optimum bulk containers are fully reusable and recyclable at the end of their life cycle, ensuring a seamless eco-friendly solution.

Product specs

Dimensions

Loading & Stacking

Other products in this line

Comparisons - Magnum Optimum 1210 vs Stainless Steel Container vs Cardboard

Low transport cost of empty units: 182 empty containers per truck, 26 full containers per truck. Enables 14 empty units per stack.

Reduced CO₂ footprint with a foldable design that improves transportation efficiency

Easier to handle. Easy handling with pallet jack or FLT. Lighter to manoeuvre- 105kg.

Easy to fill aseptically from the top.

Low transport cost both empty and full: Units per trailer: 208 (234 without lid) Stack: 8 units (9 without lid

Easy to clean and can be collected and washed across the continent for reuse.

Made of food-grade Virgin PP material and 100% recyclable.

Non foldable, high transport cost of empty units: 24 containers per truck.

Higher co2 emissions per unit due to the fact that these containers are non-foldable

Difficult to handle, needs high care handling throughout. Heavy to move 250kg.

Can only be filled aseptically from bottom.

Higher co2 emissions per unit due to the fact that these cardboard required constant strapping for transport.

Difficult to assemble / many separate parts need to be assembled. Difficult to fill.

Takes up a lot of storage space.

Cannot be cleaned.

Not always accepted in food environments.

Dry Bulk Container FAQs.

How does adopting the Magnum Optimum 1210 impact overall cost of ownership for bulk container assets?

By replacing one-way or disposable bulk packaging, the Magnum Optimum 1210 offers a reusable foldable large container structure that significantly extends cycle life. Its robust design reduces damage and replacement frequency, foldability reduces empty return transport costs, and the high static stacking load means fewer units needed for the same volume, all driving down total lifecycle cost.

How does the Magnum Optimum 1210 support product protection and quality across the supply chain?

With smooth walls, food-grade virgin PP/HDPE construction, and two runners for structural stability, the container maintains integrity even when open or folded. This keeps bulk dry food or non-food cargo safe from deformation, contamination or damage. The design helps safeguard product quality, reduce spoilage or loss and protect brand equity.

How does this container align with sustainability and regulatory goals?

The Magnum Optimum 1210 is fully reusable across many cycles and, at end-of-life, is 100% recyclable. The foldable design reduces empty return volume, lowering fuel and CO₂ emissions. This supports circular economy objectives and helps companies meet packaging-waste and producer-responsibility regulations.

What transport and reverse-logistics efficiencies can the container deliver?

The external dimensions with a folded height of just 325 mm when collapsed allow far more units per trailer on the return leg. That reduction in empty volume translates into fewer trucks, lower freight cost, and lower carbon emissions. The volume is 873 litres and load capacities are high, meaning fewer containers are needed per shipment.