How to reduce risks and boost food safety in the meat industry

In this article

Meat processors struggle to fill open positions and keep well-trained employees on staff. The numbers bear this out. Consider the following data:

- The workforce for butchering alone is expected to decrease by 2% between now and 2033.

- Nearly two-thirds (62%) of meat, poultry, and seafood processors have identified labor shortages as their biggest operational challenge in recent years.

- Approximately 20.6% of U.S. manufacturing plants, including those in the meat industry, reported operating below full capacity due to insufficient labor or skills, underscoring the profound impact of workforce shortages on production.

The effects of these shortages are multifold, but they have particular impact on food safety.

How labor shortages impact food safety and production

A shrinking workforce creates gaps in food safety and handling. Processing plants, warehouses, and distribution centers rely on experienced workers to maintain sanitation, prevent cross-contamination, and ensure meat is handled properly. With fewer trained employees overseeing these critical steps, mistakes increase, delays grow, and contamination risks become harder to control.

This staffing gap affects operations in several ways:

- Food safety concerns: Fewer sanitation and quality control workers make it harder to prevent contamination, temperature abuse, and packaging failures that expose meat to bacteria.

- Shrink and delays: Corrugated packaging weakens in cold storage, absorbs moisture, and collapses under pressure, leading to increased waste, repacking delays, and disruptions in delivery schedules.

- Strain on existing workforce: Teams spend extra time repacking damaged shipments, handling inconsistent packaging, and correcting issues, which raises injury risks, slows production, and disrupts workflows.

- Difficulty meeting regulatory obligations: FSMA and USDA compliance require strict contamination controls, but staffing shortages means fewer team members to uphold best practices, increasing the chance of recalls, fines, and regulatory scrutiny.

Without solutions, these challenges escalate. Labor shortages are expected to continue, and processors need reliable systems to prevent contamination, reduce handling errors, and support compliance.

By integrating automation, AI-driven monitoring, and standardized reusable packaging, companies can reduce manual handling while maintaining food safety standards.

Finding solutions to problems

Because of the labor pinch, more meat processors are using artificial intelligence (AI) and automation where possible to help resolve these food safety challenges.

Robotic butchering, for instance, is being introduced to reduce reliance on humans for these repetitive tasks, while more packaging lines are being automated to improve speed and precision.

Processors are also turning to AI for real-time tracking and monitoring.

Consider this scenario: A meat processing warehouse storing various cuts of beef.

The warehouse uses AI systems to track each pallet in real time, keeping records of the arrival date and designated shelf life. As a pallet of steaks approaches its expiration, AI automatically generates a pick list, ensuring the pallet closest to expiration is shipped out first to minimize product waste.

Simultaneously, sensors in a cold storage room detect a slight temperature and humidity increase. Before bacteria can proliferate, the facility manager receives an instant alert, letting them address the issue immediately to maintain product quality.

While AI and automation can benefit food safety by reducing human error, improving traceability, and ensuring proper handling, they must also be integrated with packaging and logistics.

If they aren’t integrated, inefficiencies, miscommunication, and product damage can still occur, leading to costly errors instead of improved outcomes.

For example, suppose your business relies on corrugated boxes to ship ice-packed meat, and your automation systems are not calibrated for inconsistent packaging integrity. In that case, the risk of box failure increases—and defeats the purpose of automation.

Investing in standardized packaging to improve food safety in the meat industry

While AI is a helpful tool in reducing food safety risks, it’s not the only answer. The right packaging solution can provide much-needed defense against contamination risks.

A more hygienic alternative to corrugated boxes

Reusable plastic containers (RPCs) are more hygienic than single-use corrugated boxes.

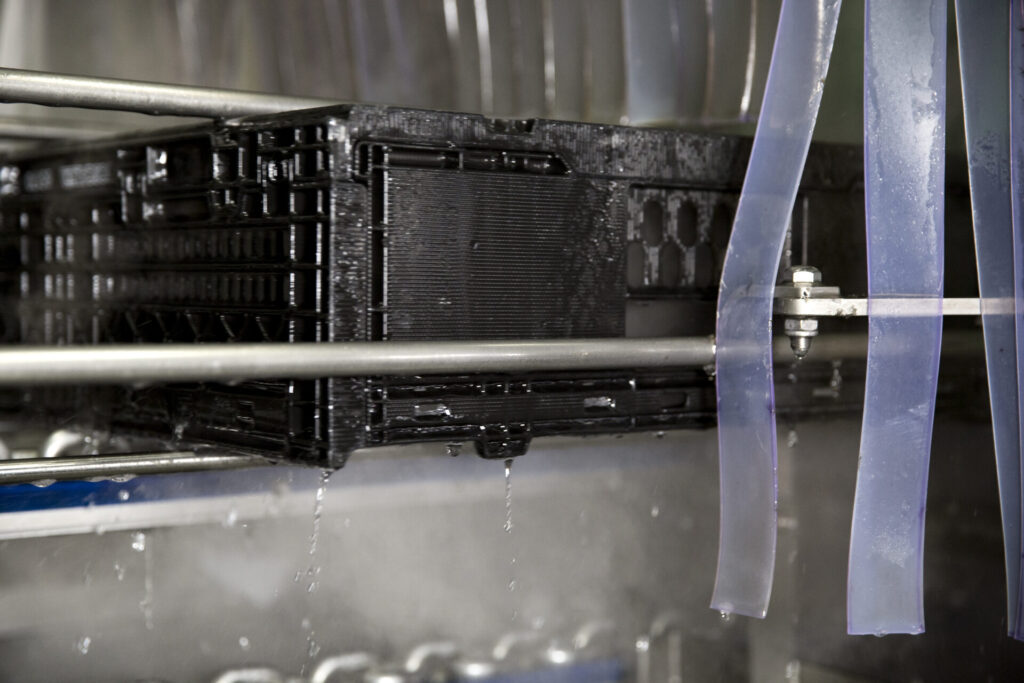

Unlike cardboard, which absorbs moisture and harbors bacteria, RPCs are designed for repeated use and thorough sanitization after each cycle. For example, Tosca’s RPCs undergo an ISO 22000-certified wash process, the industry’s most stringent wash process, which keeps foodborne illnesses at bay.

This significantly reduces the risk of cross-contamination between shipments.

Preventing packaging failures that lead to contamination

Consider the earlier example of vacuum-sealed ground beef transported in corrugated boxes. If RPCs had been used instead, the risk of packaging failure would have been eliminated.

Unlike corrugated boxes, which weaken under stress, absorb moisture, and break apart upon impact, RPCs maintain their structural integrity throughout transport. This ensures that even if a pallet shifts during handling, the packaging remains intact, reducing the chances of contamination.

Standardized packaging increases labor efficiency

The meat industry’s labor shortages make efficiency critical. Standardized RPCs help streamline operations in several key ways:

- Consistent sizing simplifies automation, reducing errors and manual handling.

- Easier stacking and handling reduce strain on workers, lowering the risk of workplace injuries.

- Eliminating reliance on fragile one-time-use packaging reduces time spent dealing with damaged shipments.

With less handling complexity, teams can work faster while maintaining food safety standards.

Optimizing logistics and reducing waste

Supply chain efficiency depends on maximizing transport and storage space. Standardized RPCs:

- Improve truck and warehouse utilization with uniform sizing

- Eliminate packaging waste from discarded corrugated boxes

- Reduce damage-related losses, preventing product shrink caused by weak packaging

Unlike cardboard, which tears, crushes, or becomes waterlogged, RPCs are made from durable plastics that withstand repeated use, providing reliability for meat industry businesses up and down the supply chain.

Better traceability, faster recalls

Traceability is critical for food safety, especially during a recall. Standardized RPCs:

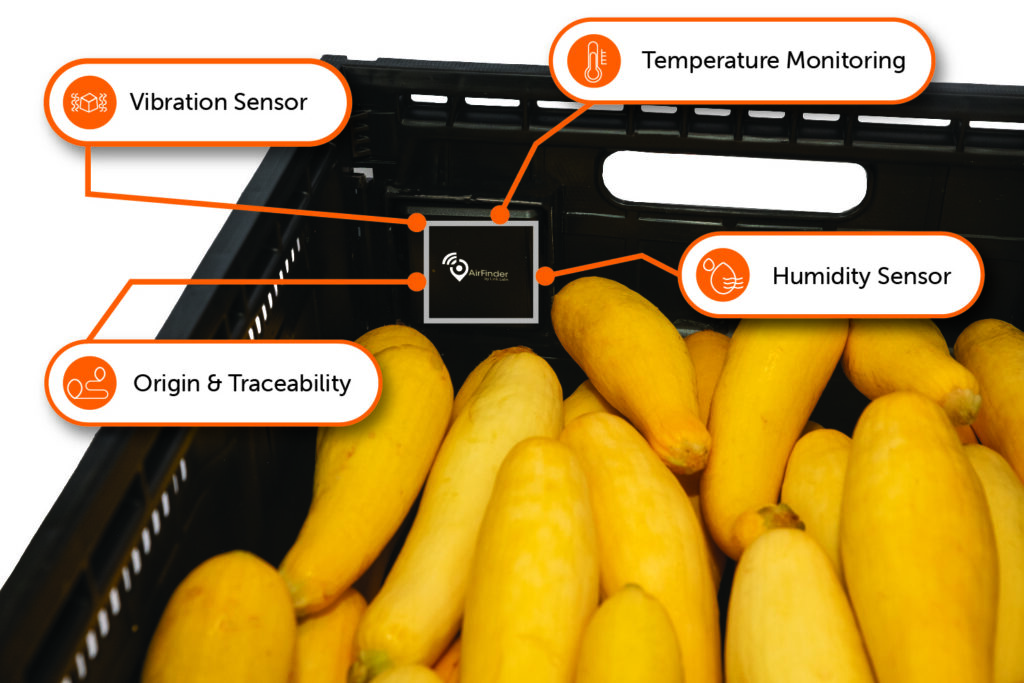

- Support RFID and IoT-enabled tracking, like Tosca’s Asset IQ, creating real-time visibility of shipments

- Allow for targeted recalls, reducing the need to remove entire batches when only specific pallets are affected

- Enhance inventory accuracy, making it easier to trace products back to their origin

By integrating packaging with tracking technology, processors can quickly spot and remove compromised products. This minimizes financial losses while putting consumer safety at the forefront.

Ready to elevate your packaging?

If you’re ready to incorporate RPCs into your food safety strategy, we’re here to help. Discover how Tosca’s RPCs for the meat industry can make a difference.