In this article

Secondary packaging might not be the flashiest part of your supply chain, but it’s one of the most critical. When it fails, product quality suffers, food safety worries arise, shelves sit empty, and profits disappear.

Additionally, secondary packaging is also a sustainability issue. Approximately 30% of the global food supply is lost or wasted each year, with packaging contributing significantly to this loss. Crushed boxes, spoiled shipments, or inadequate cold chain protection can cause shrink before they even reach the shelves.

And when they do? They often won’t sell if the packaging is damaged, contributing to the $18 billion worth of food that goes unsold in the United States annually.

These concerns are driving many food industry businesses to switch from corrugated to reusable plastic containers (RPCs). But how do you choose the best RPC provider to partner with? Start by asking the right questions.

Four areas to evaluate when looking for an RPC provider

Not all RPC vendors are equal. The best ones become an extension of your supply chain, helping you waste less, move faster, and operate efficiently.

Here are four areas to consider when evaluating RPC providers:

Network and reliability

Your RPC program is only as strong as the network behind it. If your provider can’t pick up or deliver your containers when you need them, everything falls apart quickly.

When you’re choosing an RPC provider, you need to make sure they have:

- Geographic coverage that aligns with your distribution footprint

- The ability to support seasonal spikes

- Service response times that match the needs of your operations

- Conveniently located wash facilities that can handle all of your assets

In addition to the necessities, pooling—a system where businesses share a “pool” of reusable assets—is a nice-to-have that further boosts reliability.

In pooling programs, the RPC provider supplies, manages, services, cleans, and delivers the RPCs where and when you need them. Tosca’s pooling program, for example, has an extensive wash network so you can always have the right amount of clean assets when you need them.

Questions to ask:

- How do you ensure asset availability during our peak season?

- How do you handle volume fluctuations?

- Where are your wash sites located, and what’s their daily capacity?

- Do you have a pooling program? If so, how does it work?

- How quickly can you respond and handle service disruptions or emergencies?

Experience, partnership, and support

Experience matters, especially when selecting a new packaging partner. The broader your partner’s knowledge, the better the partnership, and the more proactive support they can provide.

An experienced partner can help you create a pilot program that enables you to establish new packaging processes that work for your business.

For example, Tosca’s pilot program lets you test in a small, controlled scope and observe the impact across your actual workflows with no obligation to sign up after your trial ends.

And after roll-out, they shouldn’t vanish into thin air. A great provider stays involved well after launch, giving you the tools, training, and support you need to make sure your program runs smoothly and efficiently.

Here are some of the qualities to look out for:

- A detailed roadmap and timeline

- Hands-on training and ongoing support

- Proactive solutions

- Knowledgeable, thoughtful account managers

Questions to ask:

- Can you explain your experience in [your place in the supply chain or food industry sector]?

- Do you offer a pilot program that allows us to test the RPCs in a real environment before committing to a complete overhaul?

- What’s your approach to RPC program onboarding, roll-out, and support? And what are the timelines?

- Will you provide asset training for our employees?

- How will we manage our program?

Transparency and value

Unclear contracts, hidden fees, and vague performance metrics have no place in the supply chain. Look for an RPC partner that lays everything out clearly, including:

- A comprehensive pricing structure so you know exactly what you’re paying for

- A full total cost of ownership (TCO) and cost savings analysis to help you understand the financial impact of the RPCs over time

- Flexible contract terms that allow your program to scale alongside your supply chain

- Real-time performance metrics so you can track what’s working and what’s not

- Transparent guidance to help you identify areas for improvement and offer appropriate solutions

You should also feel confident in their ability to back up their claims with real-life results and case studies from similar programs. Bonus points if they proactively bring you ideas to optimize your broader supply chain strategy.

Questions to ask:

- What are all of the potential costs beyond base pricing?

- Can you show performance data from similar operations?

- What kind of reporting will we have access to?

- How will you help us quantify our long-term cost savings?

- Are your contract terms flexible if our needs change?

Technology and compatibility

Fifty percent of food companies are investing in better supply chain tracking, and 48% are prioritizing real-time monitoring technology this year. What’s motivating this shift?

One of the major factors is the range of food industry legislation. While the US’s Food Safety Modernization Act 204 has been delayed, numerous state, federal, and international laws may impact your business.

The right RPC provider should offer compliance-aware solutions that simplify how you track and trace your products; they should also improve how you collect and analyze your supply chain data. That means:

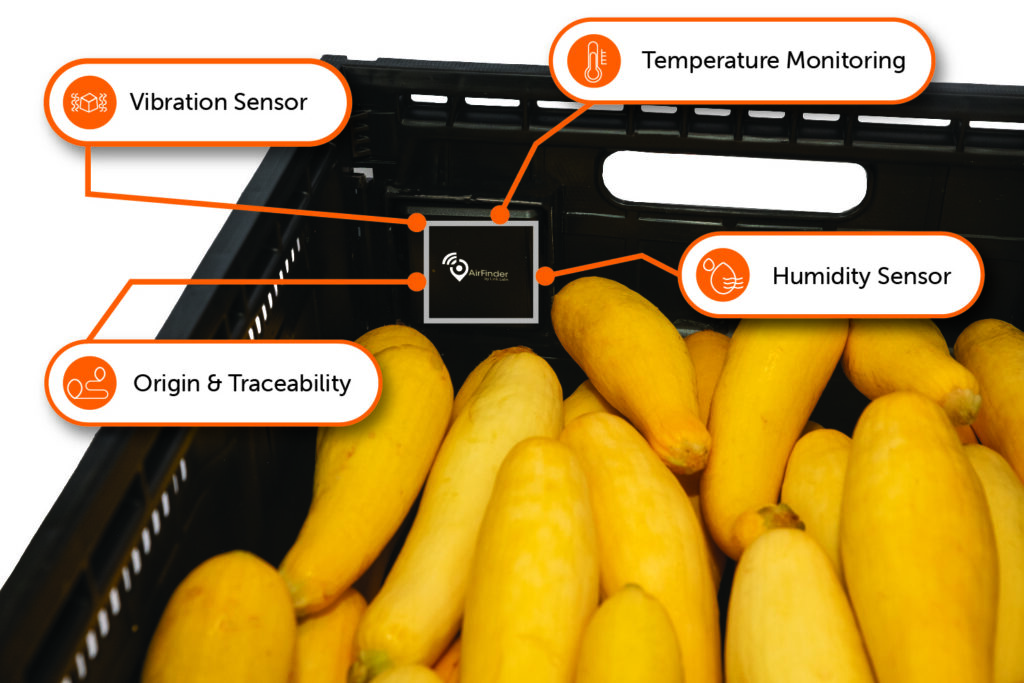

- Offering real-time visibility: They need to provide accurate 24/7 location tracking technology, allowing you to track your RPCs at all times. Tosca’s Asset IQ IoT-enabled tracking solution, for example, offers up-to-the-minute visibility.

- Ensuring seamless compatibility: Your provider’s technology must integrate seamlessly with all your systems to prevent any hiccups or delays.

- Maintaining detailed digital recordkeeping: They should have secure systems that make it easy to access, export, and analyze traceability data.

And when it comes to technology, don’t overlook the importance of automation compatibility. Fifty-five percent of supply chains are incorporating automation to address labor shortages, streamline operations, and enhance profitability. With that in mind, you need to make sure your RPCs are automation-ready.

Questions to ask:

- What kind of tracking and visibility do your containers offer?

- Are your RPCs compatible with automated systems?

- What are your practices for maintaining data security?

- Can your systems easily integrate with our existing tech stack?

What are the red flags when evaluating RPC providers?

As you evaluate RPC providers, keep your eyes open to what’s being offered and what’s missing, too. Even the strongest RPC solution can fall apart in practice if the provider is showing any red flags, some of which include:

- Limited geographic coverage

- No clear traceability strategy

- Vague responses about compliance capabilities

- No measurable KPIs

- Technology that doesn’t integrate with your current systems

- Lack of compatibility with automated systems

- Subpar support services

- No clear training or education plans

- Complex pricing with hidden costs

- Poor responsiveness during evaluation

- Inability to provide customer references

- Taking a one-size-fits-all approach

- Weak industry experience

Making the right choice

Your RPC vendor is more than a packaging provider. They should be an active partner helping you build a smarter, compliant, and resilient supply chain.

At Tosca, we do just that. With 60+ years of industry experience, 15,000+ partnerships, strong piloting, constant asset visibility, and the most extensive wash network in North America, we don’t deliver RPCs. We deliver confidence and real results.

Ready to see the impact for yourself? Start with a pilot program. We’ll prove the value with no strings attached. Contact us to get started.