Automation advising: We’re with you from concept to build-out

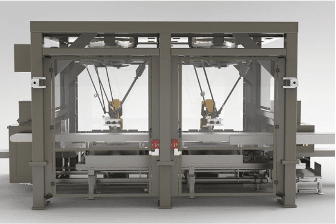

With widespread labor challenges and the need to quickly move food along the supply chain, many of our partners turn to automation. Whether you’re just beginning your automation journey or are partially or fully automated, Tosca can improve your planning and efficiency.

Key questions when considering automation

Before proceeding with an automation roadmap, we help you explore several critical questions to avoid costly mistakes and unnecessarily long timelines.

Does automation make sense now?

Large-scale automation is not the immediate answer for the vast majority of companies. Improving efficiencies will make for a smoother transition to automation later.

Do you have a broad enough perspective to improve efficiency?

Different viewpoints, including several external observations, can expose hidden inefficiencies that drain resources and signal spillover inefficiencies that need to be addressed downstream.

Are your processes and systems fully optimized?

Automation is not possible without an updated and optimized warehouse management system. A fully optimized system aids with scheduling and ensures employees do the right jobs at the right time.

Do you have buy-in from the right people?

One of the biggest challenges in making changes is overcoming workers’ resistance to anything new. Ensuring buy-in from a variety of internal audiences is key to effective and successful change management.

Automation opportunities

As answers to these critical questions help shape your path forward, we can begin to explore several areas that benefit greatly from automation, such as: