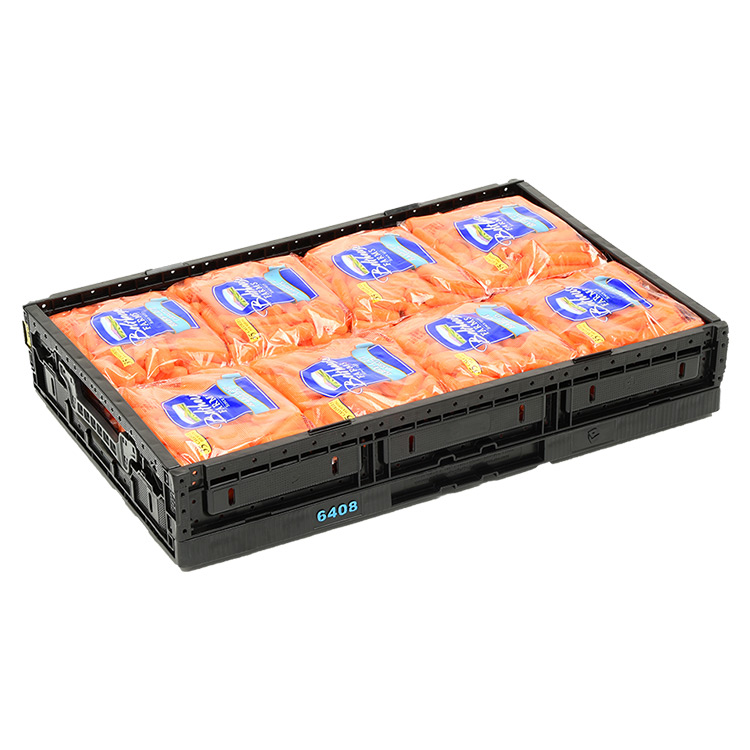

Produce 6425 produce 6425 plastic produce containers

Protect delicate produce

This lightweight RPC is the perfect choice for shipping produce directly from distribution centers to store shelves. Its low weight makes it easy to handle, and its durable plastic construction is far stronger than corrugated, ensuring the safe arrival of even fragile contents.

Product Details & Benefits

Available now to pool by the truckload (6,600 units)

Reduces shrink/product damage.

High-strength plastic protect products better than corrugated, preventing waste and reducing shrink.

Saves on labor.

Straight-to-shelf design simplifies restocking.

Saves space.

Foldable and stackable, to maximize truck and store space.

Food safe.

With the highest food safety program in the industry, containers protect products from harmful bacteria.

Supports sustainability.

Prevents the waste of single-use containers with a reusable, recyclable alternative.

Product specs

Dimensions

LOADING & STACKING

Other products in this line

Produce RPCs vs Cardboard

Produce RPC crate folds easily without pressure and locks securely, saving time and effort.

Durable reusable plastic protects produce from damage during transport, reducing food waste.

Foldable and stackable design maximises truck and backroom space, lowering costs.

Food grade reusable plastic meets food safety regulations and ensures food quality.

100% reusable and recyclable plastic crate, reduces single-use waste and carbon emissions.

Requires manual folding and taping, increasing labour time and complexity.

Prone to tearing and crushing, leading to increased product loss and higher waste.

Collapses when stacked, resulting in inefficient use of space and higher costs.

Difficult to clean and can harbour bacteria, compromising food safety.

Single-use only, contributing to higher waste levels, frequent replacements, and more impact.

Produce RPC FAQs.

How does the Produce 6425's superior stack stability help improve pick-rate in high-volume operations?

The Produce 6425’s superior stack stability directly improves pick-rate by creating a safer and more reliable product flow. The crate’s interlocking design ensures stacked units remain secure and prevents shifting or toppling, which is common with single-use packaging. This stability allows workers to pick products quickly and confidently without interruption, reducing the time spent on manual adjustments, minimizing accidents, and accelerating the overall throughput in high-volume distribution centers (DCs).

What measurable gains in lead-time and OTIF can the 6425 deliver for long-haul produce transportation lanes?

The 6425 delivers measurable gains in lead-time and OTIF (On-Time In-Full) delivery by addressing common supply chain failures:

Reduced Damage: The rigid, interlocking plastic structure prevents crushing, minimizing damaged goods and rejections, which ensures a higher In-Full delivery rate.

Faster Cooling: The crate’s ventilated design allows air to circulate more efficiently, leading to faster cooling, reducing spoilage, and overall lead-time.

How does the standardized design of the Produce 6425 crate improve versatility and load stability for various produce types?

The Produce 6425’s standardized footprint (600 x 400 mm) makes it highly versatile because it can be used for a wide range of produce, eliminating the need for various non-standard containers. This standardization, coupled with its interlocking stacking features, ensures superior load stability. Regardless of the produce type inside, the uniform crates interlock securely on a pallet, preventing movement during transit and maintaining product quality from farm to store.