Superior Hybrid Reusable bulk transport packaging

Hygienic, efficient storage & transport

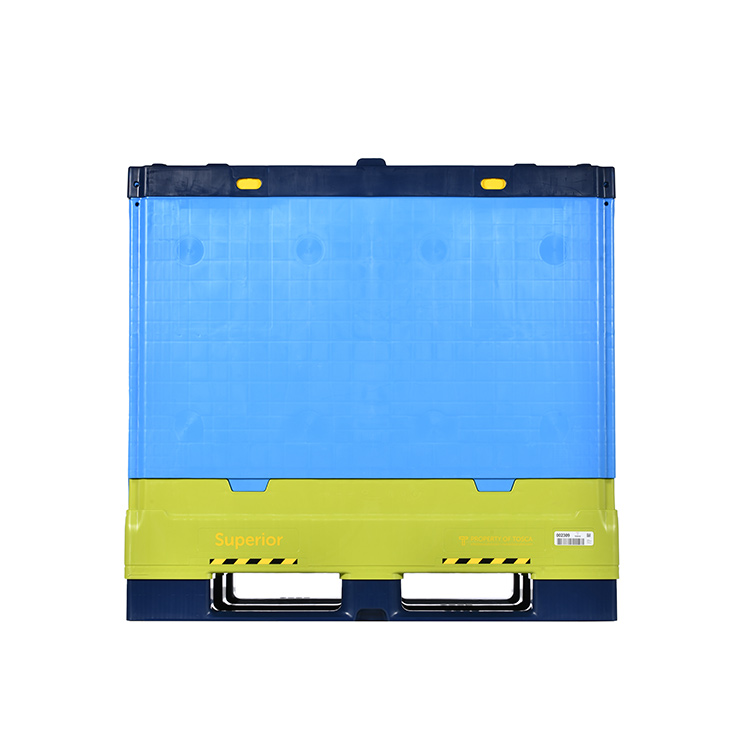

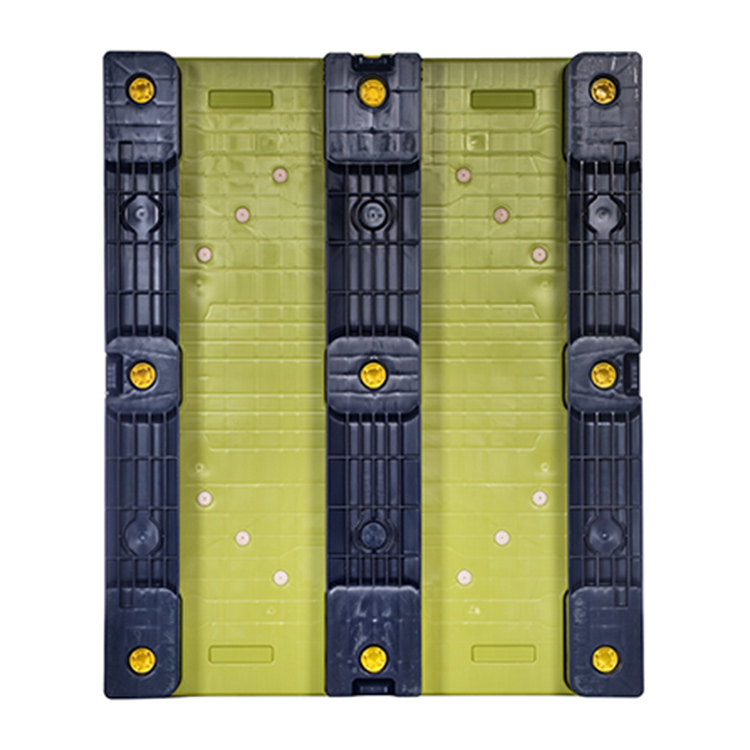

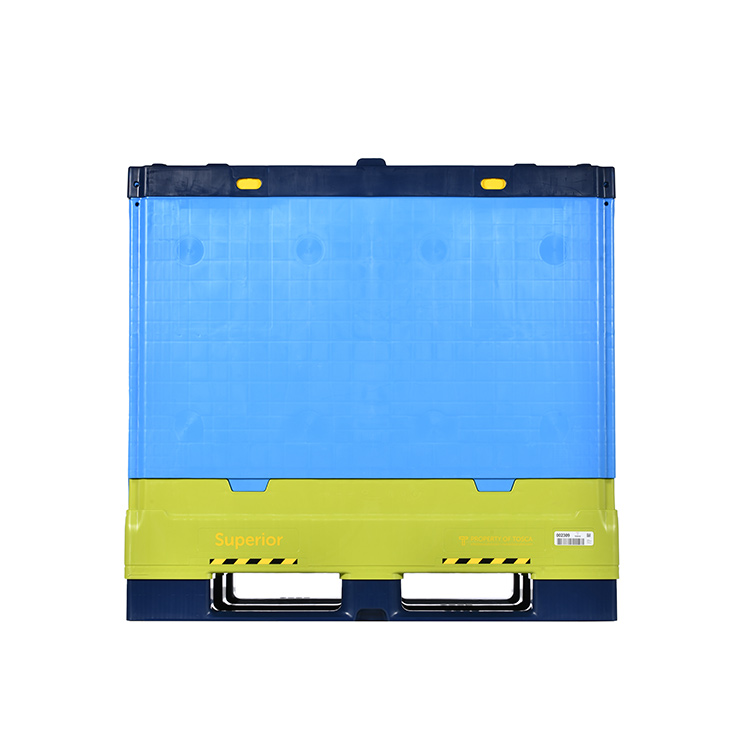

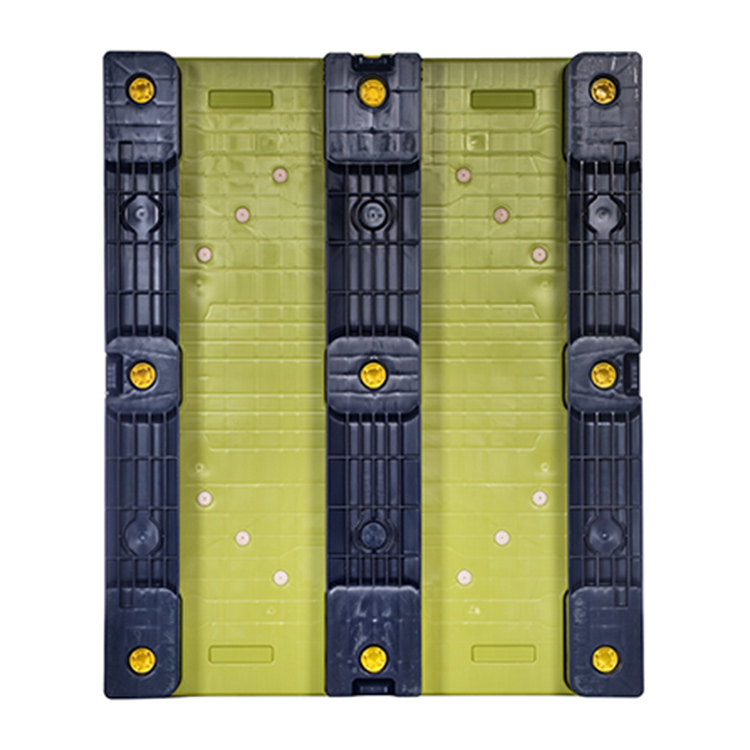

The Superior Hybrid is a food-grade foldable 1000-liter container ideal for low- and high-viscosity liquid products. It features 5 different sealable exit and entry points, and once the container is sealed, the product inside is impossible to access. The container also features a drop door, 3 runners for easy handling, and a bottom discharge to minimize residual product. Additionally, its high folding ratio saves space in storage and transit, resulting in reduced costs and a smaller carbon footprint.

Product Details & Benefits

Hygienic

Plastic containers are nonporous and resistant to moisture, insects, fungi, acids, fats, solvents, and odor. Our containers are inspected after every turn to make sure they meet our quality standards.

Sustainable

Plastic containers are ultra-durable because they can be reused for years, then get recycled and remanufactured into new containers.

Built for automation

Because plastic containers are molded, the sizes and weight are always consistent, causing zero disturbances in your automated material handling systems. Unfolding and folding can be done by only 1 operator.

No transport restrictions

Plastic export containers are ISPM-15 proof.

Traceable

RFID, GPRS, and IoT technology can be embedded, ask us for more information.

Product specs

Dimensions

Loading & Stacking

Choosing the Right Container: Superior Hybrid vs. Traditional Options

The Superior Hybrid container surpasses traditional options, maximizing floor space and improving sales through its retail-ready design.

Low transport cost of empty units: 182 empty containers per truck, 26 full containers per truck. Enables 14 empty units per stack.

Low residue in liner with advanced technology for use with viscous liquids.

Reduced CO₂ footprint with a foldable design that improves transportation efficiency.

Easier to handle. Easy handling with pallet jack or FLT. Lighter to manoeuvre -105kg.

Easy to fill aseptically from top or bottom.

Easy to clean and can be collected and washed across the continent for reuse.

Made of food-grade Virgin PP material and 100% recyclable.

Non foldable, high transport cost of empty units: 24 containers per truck. Not stackable

Residual viscous product can become attached to the interior.

Higher co2 emissions per unit due to the fact that these containers are non- foldable.

Difficult to handle, needs high care handling throughout. Heavy to move 250kg.

Can only be filled aseptically from bottom.

Takes up a lot of storage space.

Higher co2 emissions per unit due to the fact that these cardboard required constant strapping for transport.

Difficult to assemble / many separate parts need to be assembled. Difficult to fill.

Cannot be cleaned.

Not always accepted in food environments.

Superior Hybrid FAQs

How does the Superior Hybrid bulk container optimize efficiency in bulk liquid storage and transport?

The Superior Hybrid bulk container improves efficiency with a foldable design, bottom discharge system, and sealable ports. It stacks more than twice as high to save floor space, and when empty, 182 units fit on a truck versus just 26 rigid containers—cutting transport costs. Reusable, recyclable, and automation-ready, it reduces waste, labor, and carbon footprint while maintaining hygiene.

What makes the Superior Hybrid container hygienic and suitable for food-grade applications?

The Superior Hybrid container is made from an easy-to-clean, non-porous food-grade polymer that resists moisture, insects, and fungi. For additional safety, it is designed for use with liners, which provide a sterile barrier for aseptic filling, ensuring the product inside is protected from contaminants.

Are Tosca's Superior Hybrid containers compatible with automated material handling systems?

Yes, Tosca’s Superior Hybrid containers are fully compatible with automated material handling systems. With a standardized design and built-in pallet base featuring three runners, they eliminate the need for a separate pallet and integrate seamlessly with forklifts, pallet jacks, and into automated processes, improving operational efficiency.