In this article

As 60% of companies seek to enhance the resilience of their supply chains, many are exploring options beyond traditional corrugated boxes. This shift aims to reduce waste, improve efficiency, and achieve sustainability goals, and reusable plastic crates (RPCs) are a leading choice to help achieve these goals.

However, corrugated is well ingrained within the supply chain. Changing from corrugated to RPCs can be a heavy lift for businesses with the mentality of “that’s what we’ve always used.”

Still, sticking with the status quo comes with costs. Corrugated may feel familiar, but it holds supply chains back– easy to overlook until they’re causing real problems. Let’s break down how reusable packaging outperforms corrugated packaging, and how switching to RPCs can create a stronger, more resilient supply chain.

#1. Corrugated boxes fail in wet conditions

If you have perishables, you have moisture—a reality of grocery supply chains. Temperature fluctuations, especially if warm air meets cooler surfaces, during transportation or storage, can cause moisture to accumulate on the packaging.

Even waxed corrugated boxes aren’t moisture resistant; and when moisture—whether from condensation, melting ice, or even leakage from packages—seeps into the paperboard layers, the box’s structure weakens, compromising the integrity of the products inside.

Moisture can reduce durability by as much as 40%, significantly increasing the risks of tears, contamination, and box failure.

RPCs are made of sturdy plastic, so they don’t break down when exposed to moisture.

Unlike corrugated boxes, they maintain strength even when exposed to humid environments, ensuring products remain protected in wet conditions.

RPCs also have enhanced ventilation features, which encourage the necessary cooling for meat and eggs and maintain the freshness of perishable goods, reducing shrink by 50%.

#2. Corrugated boxes are less durable than you’d think

Fragility is one of the most pressing challenges of corrugated boxes—and it’s not just caused by moisture. If boxes are filled too heavily or stacked too high, they lose their ability to support the contents. This can lead to crushing, collapsing, or falling over, causing damage and food waste.

RPCs are made from durable polypropylene and have been proven to be 4x stronger than corrugated boxes, providing superior product protection.

RPCs are also engineered to interlock, creating better load stability, so you can stack higher without worrying about the stack tipping. Their solid construction and automation-ready standard footprint enable smooth movement through machinery. This minimizes interruptions and keeps workflows moving.

#3. Corrugated boxes cause space inefficiencies

When it comes to shipping, space is a valuable commodity. Corrugated boxes come in a variety of sizes and shapes, making it hard to optimize cube utilization in a truck or warehouse.

This inefficiency leads to wasted space, which means more trips are needed to transport the same amount of goods. And more trips mean more fuel, higher emissions, and greater transportation costs.

RPCs, on the other hand, are designed to stack together securely. The uniform size of Tosca’s RPCs makes it easier to use every inch of cube space to its optimum capacity—stacking up to 96 inches high, resulting in fewer trips, reduced emissions, and lower related costs.

#4. Corrugated boxes won’t always be recycled

Corrugated packaging can only be recycled around 5–7 times. In some cases, it can’t even be recycled once: 30% of used corrugated goes straight to the landfill. The culprit? Contamination.

Corrugated boxes that are coated in wax or soiled can’t be recycled, contributing to the growing amount of global landfill waste, which is projected to reach 3.8 billion tons by 2050.

Each RPC can be sanitized and reused over 100 times before being recycled into new containers, supporting a circular economy. In fact, Tosca has helped divert over one million tons of corrugated cardboard from supply chains, reducing landfill waste and preventing the equivalent of 3.8 million tons of CO2 emissions from entering the environment.

#5. Corrugated boxes are difficult to handle

Handling corrugated boxes is often awkward, especially if they are damaged. Without ergonomic handles, workers risk dropping boxes or injuring themselves as they struggle to move heavy, inconveniently shaped boxes.

RPCs are designed with standard ergonomic handles, making lifting and carrying easier and safer by eliminating the need to handle bulky, unwieldy boxes. RPCs improve both speed and safety in store operations.

#7. Corrugated boxes require more waste management and labor

Corrugated boxes need to be disposed of or recycled after just one use. Managing this single-use packaging waste can be costly and time-consuming, as it involves organizing pickups, handling disposal, and ensuring proper recycling if the boxes aren’t soiled.

There are also hidden labor costs of working with corrugated boxes, such as breaking them down with box cutters and taking multiple trips to the baler. This makes the supply chain less efficient than it could be.

In contrast, when an RPC reaches the end of its life, it can be recycled into a new RPC, closing the loop on waste.

#8. Corrugated boxes aren’t easy to trace

Corrugated boxes make tracking products accurately throughout the supply chain difficult since they lack built-in tracking capabilities. This isn’t only problematic for general inventory management and movement. In the event of a recall, these traceability challenges slow down the process of identifying and isolating affected products before they reach consumers.

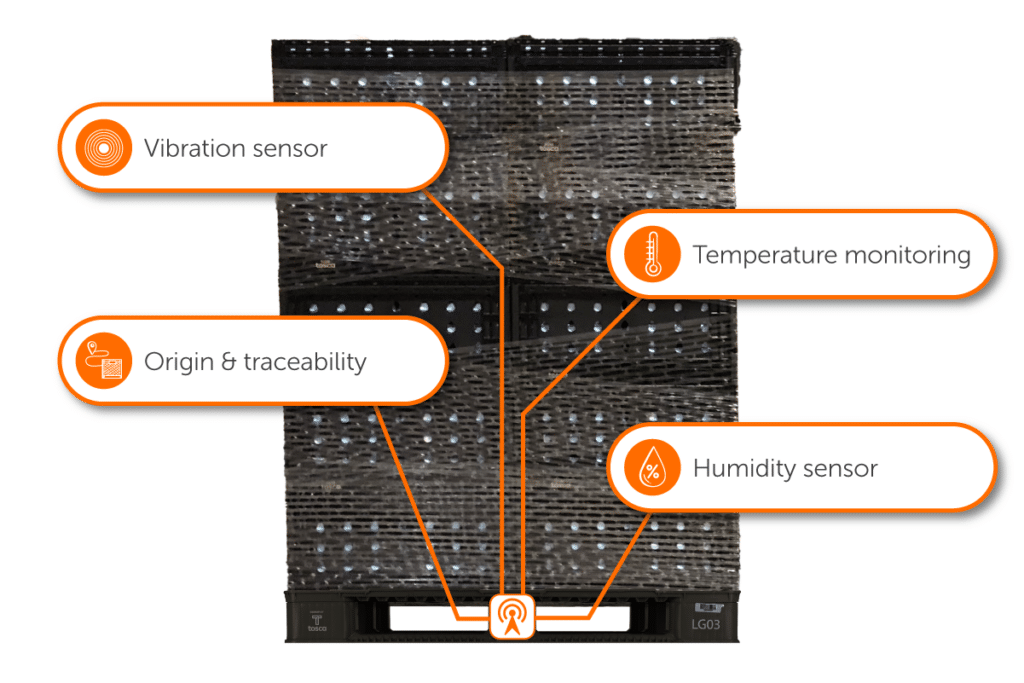

Tosca’s RPCs are designed for traceability from the start. With RFID technology and barcodes integrated into each container, businesses can monitor the location of their products enhancing supply chain efficiency and inventory management.

The reusable nature of RPCs also means that valuable data accumulates over time, allowing companies to optimize their operations and reduce the risk of lost or misplaced packaging. This level of visibility streamlines logistics and improves overall inventory management.

Creating a more sustainable supply chain with reusable packaging

A future where supply chains are more resilient, products remain fresher, and packaging is optimized for both cost and sustainability doesn’t have to be a distant vision. With Tosca’s reusable packaging solutions, that future is now. By switching to RPCs, you’re not just solving current challenges. You’re upgrading your supply chain operations and paving a path to long-term cost savings.

Interested in learning more about Tosca’s reusable packaging solutions? Schedule a consultation to discuss your current process, products, packaging, and goals.