In this article

Summary

As part of Tosca’s commitment to sustainability, this post is a part of an ongoing series that highlights our 2025 Sustainability Report.

This report reflects our mission to revolutionize the flow of goods through the supply chain, eliminating waste at every turn.

To effectively provide customers with transformative sustainability benefits through Tosca’s reusable packaging solutions, we’re committed to reducing our own environmental impact. By actively pursuing greater operational efficiency, often in collaboration with customers, Tosca works to conserve energy, decrease emissions, optimize water usage, and minimize waste throughout our extended supply chain.

51 % of electricity provided by the grid is renewable

“Sustainability is inherent to our business model and what we are all about. Every step we take internally to operate more sustainably and responsibly helps support our customer’s sustainability – and cost management – goals, as well as our own.”

— Jurgen van Roy, VP Operations, EMEA, Tosca

Sustainability Starts @ Tosca

- Energy Efficiency and Water: Over 51% of our electricity (grid and direct) is provided by renewable energy, and 25% of facilities have solar panels on the building. We routinely explore how we can be better water stewards as described in our Water-Wise Food Safe section.

- Waste Reduction: Over 62% of our sites recycle operational waste, in addition 100% of redundant assets in our control are sent for recycling and incorporation back into new assets: On average we have approximately 25% recycled content across our asset portfolio.

- Process Improvements: 90% of our facilities have some form of automation in place – unstacking, opening, closing, stacking, and wrapping. This improves safety, increases operational efficiency, and reduces asset damage.

- Equipment and Infrastructure Upgrades: Across EMEA, we’ve replaced 100% of forklifts with electric options. Globally we continue to implement LED lighting in facilities and are over halfway to our goal of full LED lighting in our largest footprint areas.

Progress on 2030 goals:

| 70% of facilities have LED lights installed in the largest footprint areas: Target is 100% by 2030 |

| 100% of forklifts in EMEA will be electric: Target is 100% globally by 2030 |

| 90% of facilities will have some form of automation in place: Target is 100% of sites by 2030 |

Optimizing Efficiency in Asset Design and Management

Tosca’s assets and pooled services are carefully designed to reduce environmental impacts and costs and enable compliance with regulatory requirements such as the UK Plastics Packing Tax and the EU Packaging and Packaging Waste Regulation.

Increasing the levels of recycled content across our new asset portfolio and improving durability to increase the number of uses before sending for recycling are two aspects we continuously work on.

We then trial out our concepts through customer pilot programs where we prove our full value proposition from cost reduction to durability, labor efficiencies, product shrink / loss reduction, and emissions reductions through cube efficiencies and minimizing miles. The proof of our value proposition is clear with an > 90% immediate conversion rate into full programs.

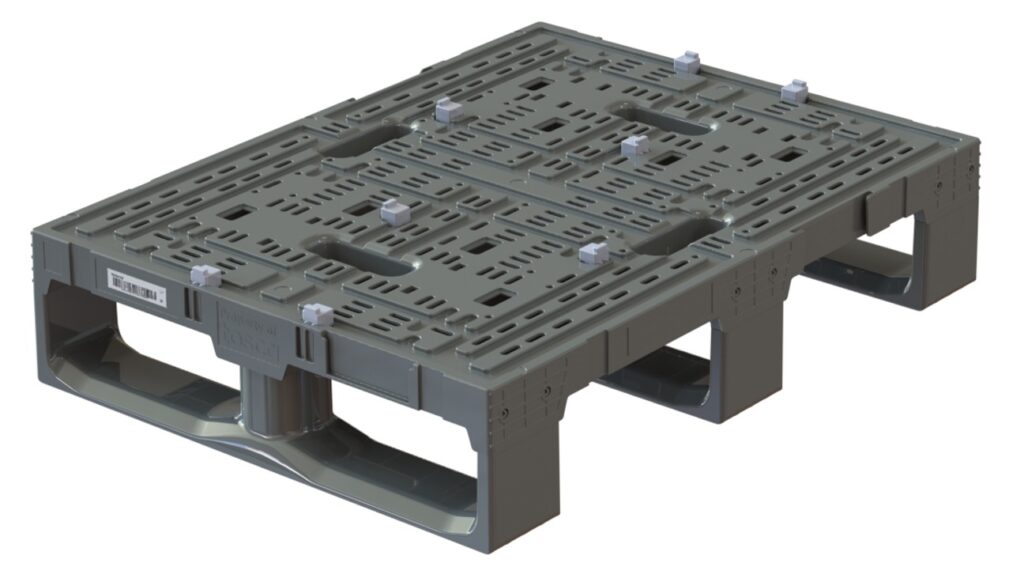

Innovating a Better Pallet

Our new Unitized Distribution Pallet (UDP) Gen 2, is lighter, longer lasting, stronger, easier to repair, and more cost-effective than its previous incarnation. All of these physical benefits lead to emissions reductions and less need for replacements.

Progress on 2030 goals:

| >30% Recycled content in UK products: Target is >30% recycled content by 2030 |

| >25% Recycled content on average across the whole portfolio: Target is >30% recycled content by 2030 |

All around sustainable products

CASE STUDY: Versova

To eliminate packaging-related contamination risks, Versova transitioned to Tosca’s reusable plastic crates (RPCs)—a sanitized, traceable, and structurally stronger alternative to corrugated boxes. The main driver for switching to Tosca RPCs was the reduction in broken eggs during transportation. The RPCs allow additional protection for the egg cartons which resulted in an average 66% reduction in egg loss. Read the full case study.

“Our strong focus on designing our assets to afford better protection of transported goods has resulted in reduced damage/shrink rates for product moved. We have seen significant reduction in produce damage shrink, over 51% of eggs moved and over 20% of total meat and poultry moved, saving our customers millions of dollars in lost sales while reducing emissions from the disposal and replacement of damaged food by 85%.”

— Holly Maher, Commercial Sales, NAM, Tosca

7X more empty foldable crates can be transported in a single vehicle compared to traditional rigid plastic crates

Logistics and Transportation Improvements

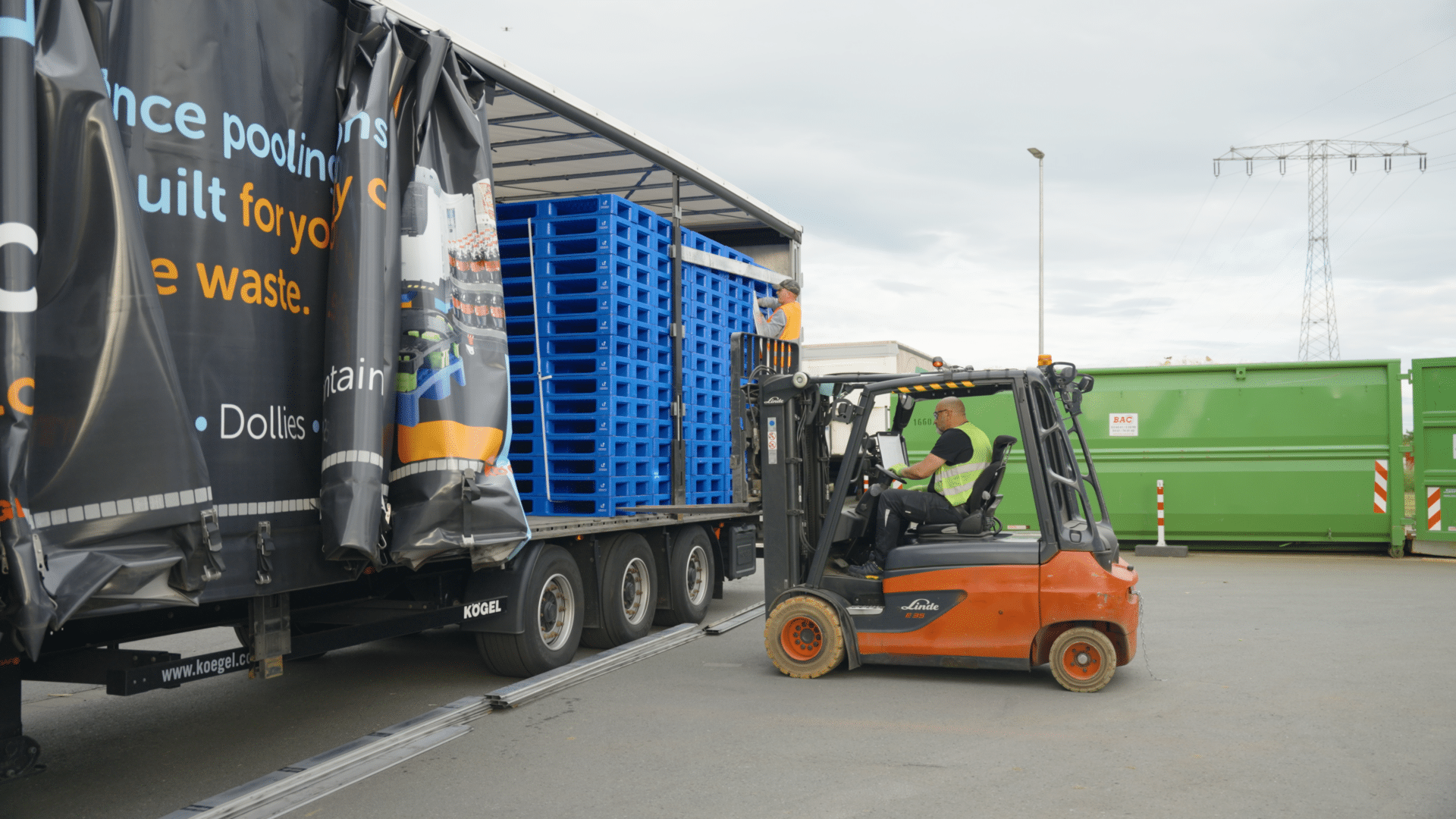

11 MT CO2e per month is eliminated through the use of our dedicated fleet

We’ve increased our dedicated logistics fleet in EMEA to over 60% of the total fleet and reduced the need for inter-company transfers (pool balancing) by over 80% through streamlined planning and improved cube efficiency. Together this has resulted in a reduction in emissions of 11 MTCO2e per month.

At Tosca, we also work closely with our logistics providers to obtain better data on miles driven and associated emissions and keep abreast of their work on increased fuel efficiency and research into alternative fuels and EV engines. In 2024, we reduced our transport distances by nearly 2 million miles and improved cube efficiency by 5% in the US alone.

Internally, we’ve accelerated transition of our EMEA company vehicle fleet to electric or plug-in hybrid models through increased offerings to team members for company cars.

47% reduction in Scope 3 emissions compared to 2023: Target is 42% reduction by 2030

Critical Insights with Asset IQ

“The ability to record and understand data is one of the most important ways a business can understand actual performance and identify areas to improve. We see huge potential for our customers to optimize efficiency in their supply chains by combining our high-quality products with the intelligent insights provided by our IoT technologies.”

— Nigel Lemmon, Chief Information Officer, Tosca

Tosca’s Asset IQ delivers critical data and insights about supply chain performance. In the future, customers will use it to find efficiencies and relieve bottlenecks, leading to better performance.

Core capabilities can include real-time asset location, the ability to pinpoint asset ‘leaks’, monitoring of asset utilization, cycle times, and overall pool efficiency.

In the U.S. UK and EU new products are already 100% RFID tagged.

Asset management is critical for both Tosca and our customers. We collaborate with customers through rigorous planning and tracking to keep assets moving through the supply chain, reducing over-purchasing and loss, while minimizing costs and emissions and elevating customer satisfaction.

Reduced asset loss means less material waste, lower manufacturing emissions and costs, and faster, safer reintegration of assets into the system for reuse.