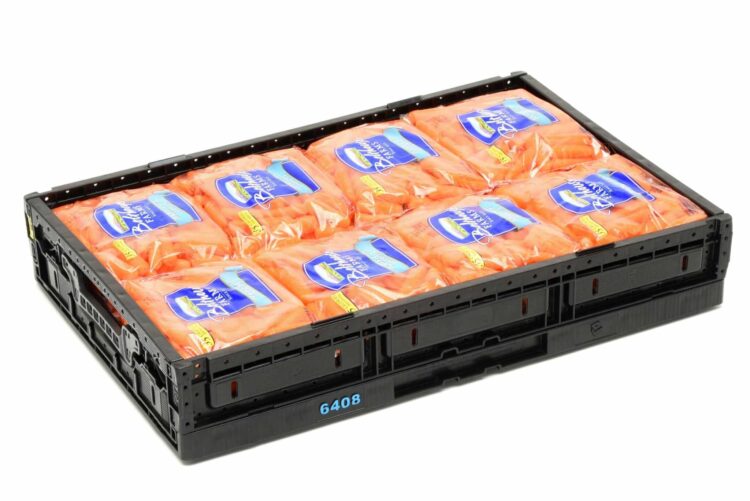

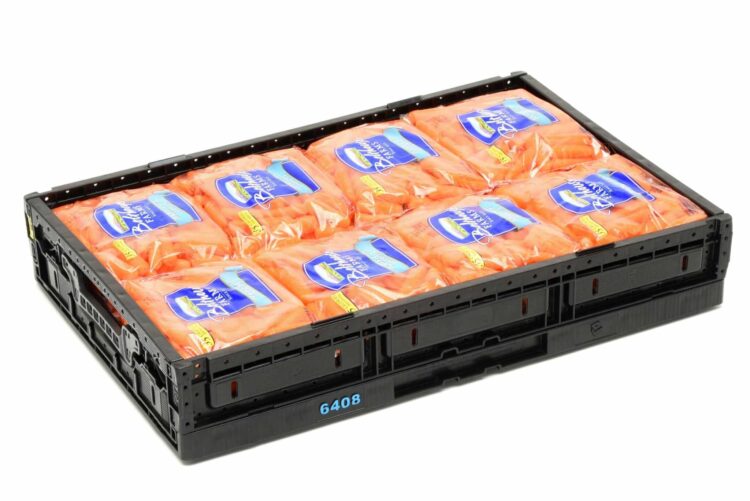

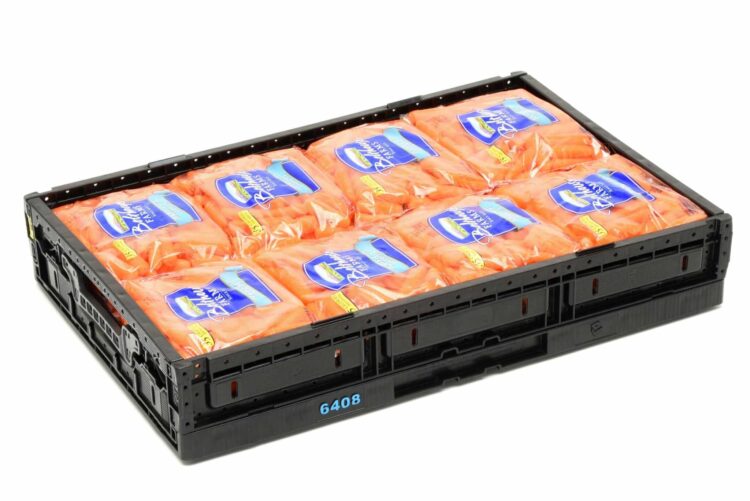

Produce 6408 Produce 6408

Lightweight, durable produce crates

This lightweight RPC is the perfect choice for shipping produce from distribution centers straight to store shelves. Its low weight makes it easy to handle, and the durable plastic construction is far stronger than corrugated, ensuring the safe arrival of even fragile contents.

Product Details & Benefits

Reduces shrink/product damage

High-strength plastic protect products better than corrugated, preventing waste and reducing shrink.

Saves on labor

Straight-to-shelf design simplifies restocking.

Saves space

Foldable and stackable, to maximize truck and store space.

Food safe

With the highest food safety program in the industry, containers protect products from harmful bacteria.

Supports sustainability

Prevents the waste of single-use containers with a reusable, recyclable alternative.

Product specs

Dimensions

Loading & Stacking

Other products in this line

Produce RPC FAQs.

How does pooling produce crates instead of buying them save money?

Instead of purchasing produce crates, pooling lets you avoid upfront capital and the ongoing costs of managing, cleaning, and storing containers, a major benefit in the seasonal produce industry. You pay only for what you use, when you use it. Tosca handles delivery, sanitization, and maintenance, turning a fixed asset into a scalable cost.

How does Produce 6408 improve airflow and shelf life compared with corrugated using ventilated produce crates?

Tosca’s Produce 6408’s ventilation design allows produce to cool up to 6x faster than in corrugated boxes. The better airflow in ventilated produce crates means temperature is kept consistent throughout the pallet, reducing hot spots that cause premature ripening and spoilage. This faster cooling and better air circulation can extend shelf life by days when compared to solid-walled corrugated.

What operational gains can we expect from reusable produce crates across harvest, DC, and retail?

When you use Tosca’s reusable, stackable produce crates, the crew can pack faster during harvest. Plus, suppliers can stack higher and use less warehouse space for cooling and storing. In DCs, standardized dimensions improve automation throughput and eliminate box failures. At retail locations, associates save time with faster backroom organization and eliminate the trip to the bailer.