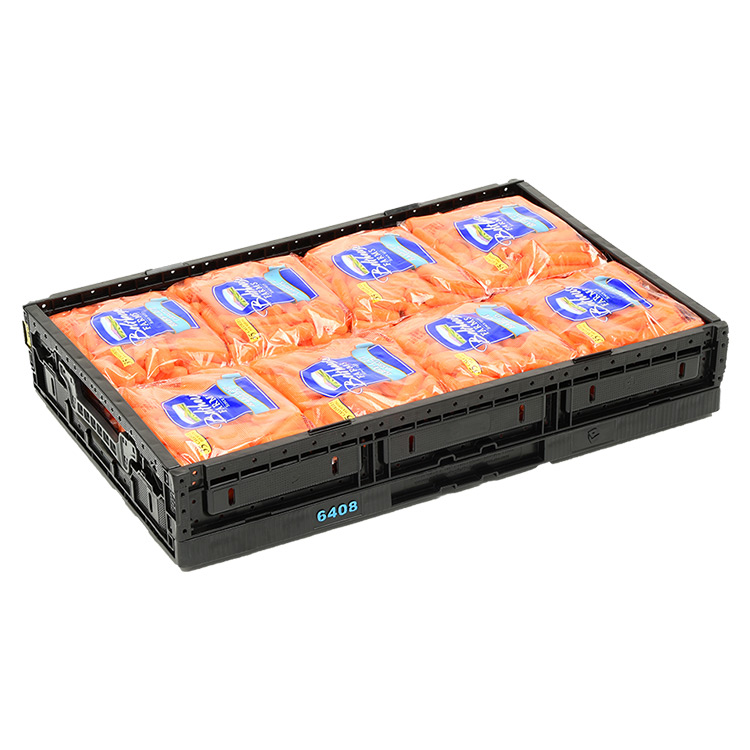

Produce 6416 produce 6416 plastic produce containers

Boost shelf life with RPCs

This lightweight RPC is the perfect choice for shipping produce directly from distribution centers to store shelves. Its low weight makes it easy to handle, and its durable plastic construction is far stronger than corrugated, ensuring the safe arrival of even fragile contents.

Product Details & Benefits

Available now to pool by the truckload (9,900 units)

Reduces shrink/product damage.

High-strength plastic protect products better than corrugated, preventing waste and reducing shrink.

Saves on labor.

Straight-to-shelf design simplifies restocking.

Saves space.

Foldable and stackable, to maximize truck and store space.

Food safe.

With the highest food safety program in the industry, containers protect products from harmful bacteria.

Supports sustainability.

Prevents the waste of single-use containers with a reusable, recyclable alternative.

Product specs

Dimensions

LOADING & STACKING

Other products in this line

Produce RPCs vs Cardboard

Produce RPC crate folds easily without pressure and locks securely, saving time and effort.

Durable reusable plastic protects produce from damage during transport, reducing food waste.

Foldable and stackable design maximises truck and backroom space, lowering costs.

Food grade reusable plastic meets food safety regulations and ensures food quality.

100% reusable and recyclable plastic crate, reduces single-use waste and carbon emissions.

Requires manual folding and taping, increasing labour time and complexity.

Prone to tearing and crushing, leading to increased product loss and higher waste.

Collapses when stacked, resulting in inefficient use of space and higher costs.

Difficult to clean and can harbour bacteria, compromising food safety.

Single-use only, contributing to higher waste levels, frequent replacements, and more impact.

Produce Crate FAQs

What are the benefits of using collapsible produce storage containers like the Produce 6416 for fruit and vegetables?

Collapsible containers like the Produce 6416 come in a standardized size which makes stacking and transport safer and more efficient, maximizing cube on pallets and trucks. Their ventilated sides cool products 6x faster than corrugated boxes, and allow air flow for optimal ripening. They do not succumb to damage under wet and damp conditions and their cost is often less than reinforced or waxed boxes.

How do reusable plastic crates help in reducing food waste and protecting perishable produce during shipping?

Reusable plastic crates like Produce 6416 are 400% more sturdier than corrugated, preventing crushing and damage that leads to food waste. With the built-in ventilation, the crates support faster and more even cooling which extends the shelf life.

How does standardization on the 6416 improve throughput in automated or mixed-SKU environments?

The standardized size and design of the Produce 6416 are key to its efficiency in automated system. The machinery does not need to be recalibrated, which improves throughput and reduces the risk of operational breakdowns.

In what ways do RPCs help minimize food waste and extend shelf life?

Reusable plastic containers (RPCs) minimize food waste and extend shelf life in three main ways:

1) Ventilation: They are designed with optimal airflow to keep produce fresh and prevent spoilage.

2) Durability: The sturdy plastic construction protects produce from being crushed or bruised, which is a leading cause of food waste in transit.

3) Labor/Retail Ready: Their design allows them to go directly from the distribution center to the store shelf, reducing the need for extra handling and repacking. This “straight-to-shelf” model minimizes physical damage and saves time and labor.