Shipping packaged poultry in corrugated cardboard: Easier said than done

In this article

The poultry supply chain is not an easy one, but many suppliers are finding some relief in shipping in an alternative container instead of the traditional corrugated cardboard box.

Poultry recently passed beef as the nation’s top selling protein. According to the National Chicken Council, “Americans buy more chicken than any other food at the center of the plate. Chicken consumption per capita has increased nearly every year since the mid 1960’s.” It’s no surprise that poultry is so popular; it is a healthier protein and usually the cheaper option. But as the market grows, retailers and poultry suppliers are feeling the strain of shipping so much poultry.

Shipping poultry is not easy. Think about the last time you went to the grocery store and picked up a package of chicken. Was it sticky? Did it have a slimy film on the plastic? Was the chicken flattened or compressed? Odds are you said yes to at least one of the previous questions. Poultry is 70% water and usually shipped with an ice crust, meaning leaks in poultry packaging are hard to avoid. Combine poultry leakers with the fact that poultry is shipped in corrugated boxes, and you’ll start to understand the issues with transporting poultry.

The first corrugated cardboard box was patented in 1871. Other than a few minor modifications, this is what is largely still used in the supply chain today: 19th century technology to solve complex 21st century problems.

And this is what we learned:

Corrugated cardboard can’t handle the realities of shipping poultry.

Supply chain and operation managers continually see issues with corrugated boxes for poultry packaging. We’ve heard these complaints again and again from our partners and customers.

The three biggest challenges for shipping poultry in corrugated cardboard:

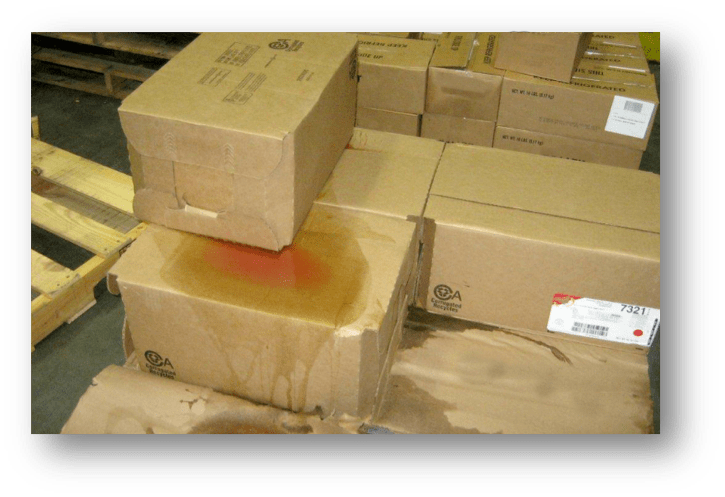

- Corrugated cardboard can’t handle moisture or water. Leakers and purge destroy the structural integrity of corrugated boxes creating box failures at many points in the supply chain. Box failures result in unsaleable product and increased labor costs since workers have to spend time cleaning up these messes.

- Poultry is heavy and corrugated cardboard can’t stand up to the weight. So when a pallet of poultry packed in corrugated boxes is stacked for shipping, it is the product inside that bears the weight of the entire stack. This creates unstable pallets for shipping and greatly impacts product quality. It also results in those sticky films on packaging that we mentioned earlier. Chicken isn’t supposed to look flat in its packaging, that happens when it’s shipping container can’t hold the weight of the pallet so the chicken has to instead.

- Corrugated cardboard boxes are a single use container that can’t be reused which means there is a lot of packaging waste generated. And, this waste has to be disposed of at the baler – which results in more wasted labor time.

Corrugated boxes are far from ideal for poultry, so we decided to do some research to see if we could build a better packaging solution for poultry. We sought feedback from poultry industry professionals – suppliers responsible for raising the birds to retailer operations and category management personnel that ultimately sell the product–to understand the pain points when shipping poultry. Then, our packaging engineers and supply chain experts went to work developing a superior packaging solution your poultry deserves.

The Tosca RPC solution for Poultry

At Tosca, we’ve created better solutions to replace corrugated boxes for shipping perishables with Reusable Plastic Containers (RPCs) – and we’ve been doing it for more than 20 years. Our new poultry packaging meets the unique needs of poultry so that product gets from farm to shelf in optimal condition.

The Tosca Poultry RPC Features:

- Engineered for durability with food grade polypropylene to withstand weight and water.

- Fluid retention channel drains liquid away from your packaged product to protect against leakers and purge.

- Optimized container dimensions allow for a 1 to 1 conversion from corrugated cardboard.

- Scalloped walls of our reusable plastic containers allow poultry to lay flat and uniform, protecting it from damage, and maximizing internal volume.

The future of the supply chain: From corrugated cardboard to RPCs

The poultry supply chain is long overdue for a packaging upgrade, and Tosca has created a disruptive solution that will change the poultry supply chain forever. Our Poultry RPC is the more sustainable packaging solution to corrugated cardboard that protects your product, creates supply chain efficiencies and lowers costs. It’s time to think outside the box.