2025 Sustainability report

At Tosca, sustainability remains at the core of our DNA. We are committed to supporting the sustainability goals of our customers, reducing the impact of our operations, and fostering a more sustainable community both within and outside our organization.

2025 by the numbers

less water invovled with RPCs than single-use corrugated packaging

trees saved from avoiding cardboard use

Olympic pools of water saved

completed food safety tests globally in 2024

of our electricity (grid and direct) is provided by renewable energy

Sustainability overview

For more than 60 years, Tosca has been a leader in reusable, recyclable transport packaging and pooling services, working in partnership with the world’s leading brands to eliminate waste along the supply chain. Our sustainability value proposition: Circular Packaging Solutions for a Sustainable Supply Chain.

Transforming the transportation packaging sector

Transportation packaging is the unseen and unsung hero of the supply chain. Procuring, storing, repairing, packing, and moving packaging efficiently while navigating regulatory requirements such as the EU Packaging and Packaging Waste Regulation (PPWR) an EPR laws, and achieving sustainability expectations is not easy from several perspectives:

Cost

Environmental

Safety

Integrated value proposition: The egg

Leaner operations, smarter outcomes

To effectively provide customers with transformative sustainability benefits through Tosca’s reusable packaging solutions, we’re committed to reducing our own environmental impact. By actively pursuing greater operational efficiency, often in collaboration with customers, Tosca works to conserve energy, decrease emissions, optimize water usage, and minimize waste throughout our extended supply chain.

Energy and water efficiency

Waste reduction

Process improvements

Equipment and infrastructure upgrades

Water-wise and food safe

Water is a precious resource. At Tosca, we’re on a mission to make every drop count in our wash cycles while ensuring that our reusable plastic packaging meets Quality and Food Safety (QFS) standards. This is particularly important to prevent the spread of foodborne illnesses. We are proud that our rigorous attention to detail when washing our reusable assets significantly supports our customers in their aim of preventing the transmission of food-related diseases.

Water use intensity

Critical defense against food borne illnesses

Playing our role during outbreaks

Regulatory compliance support

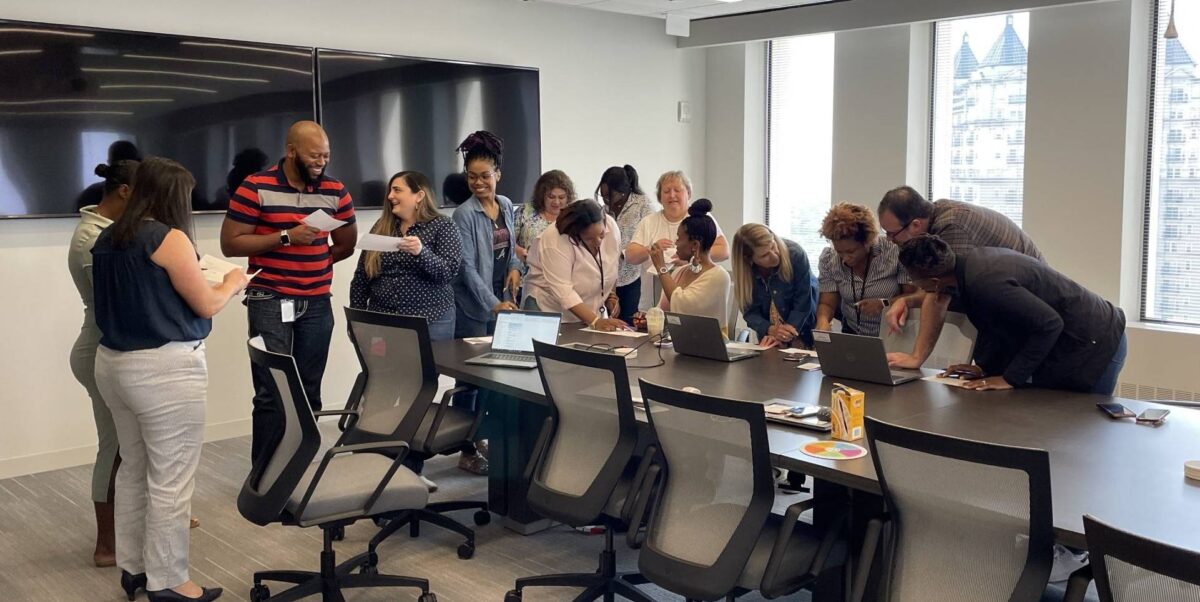

Heart of sustainability

Our people are at the heart of every innovation, improvement, and customer success we achieve. Their creativity and passion fuel the measurable impacts we deliver together. Simply put, they are the heart of Tosca.

Survey participation

Code of conduct

Pay equivalency

Employee tenure

Women in leadership

Circular supply chain

Our circular economy doesn’t end with our products — it’s embedded in how we work with suppliers across our entire value chain.

At Tosca, we see our suppliers as an extension of our own operations. Our supply chain is a dynamic network of critical third parties working in sync to help reduce waste, extend product life, and deliver impact. We apply the same high standards to every critical partner through our Supplier Code of Conduct.

Tosca’s critical supply chain partners include:

Raw material suppliers

Third-party manufacturers

Asset conditioning services

Logistics providers

Plastics regrinders and recyclers

Sustainability news & stories

Brookshire Brothers: From Corrugated Bottlenecks to Better Days with Tosca RPCs

From fragile to future-proof: Prairie Star Farms’ smart packaging upgrade

Leaner operations, smarter outcomes

Protecting eggs in a high-risk supply chain: How Versova upgraded its packaging

How the “careful consumer” is changing food retail: Trends to watch in 2025

Sustainability is in our company's DNA

Previous sustainability reports

Sustainability advising, solid steps for a lighter footprint

Whether you’re many years into your sustainability journey or at the very beginning, our sustainability experts are here to provide support from compliance to purpose.