Supply Chain Outlook: What to Expect Near-Future

The forces behind supply chains today

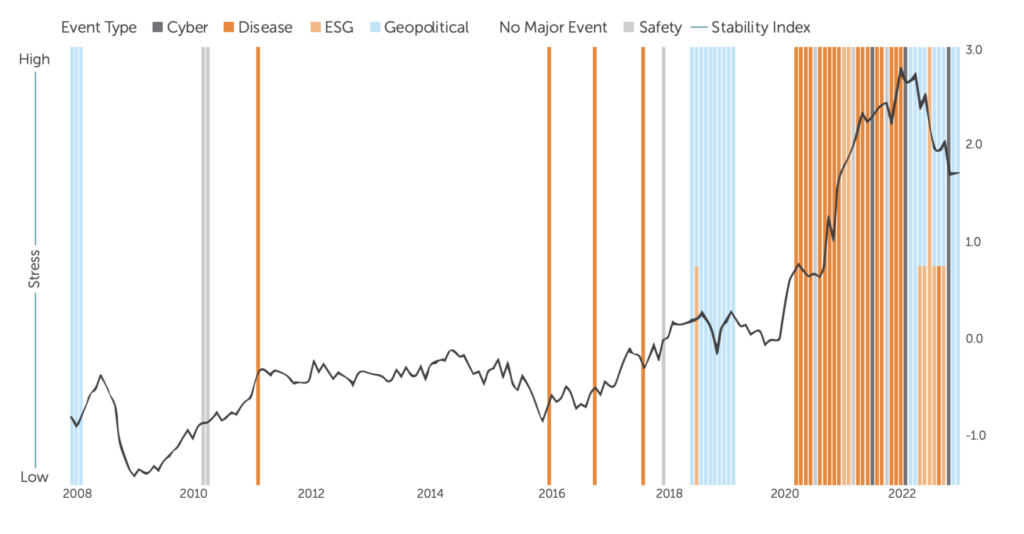

The global supply chain outlook has become highly volatile in recent years, brought on by a seismic impact of a global pandemic, a war in Ukraine, growing tensions between the US and China countries, several ecological disasters, and more. These events combined have left the industry in a constant state of recalibration, change, and tension for over three years. The companies and supply chain leaders that can keep their footing will develop strategies today that will lead to a far more resilient supply chain in the future.

Major events impacting supply chains 2008 – 2023

source

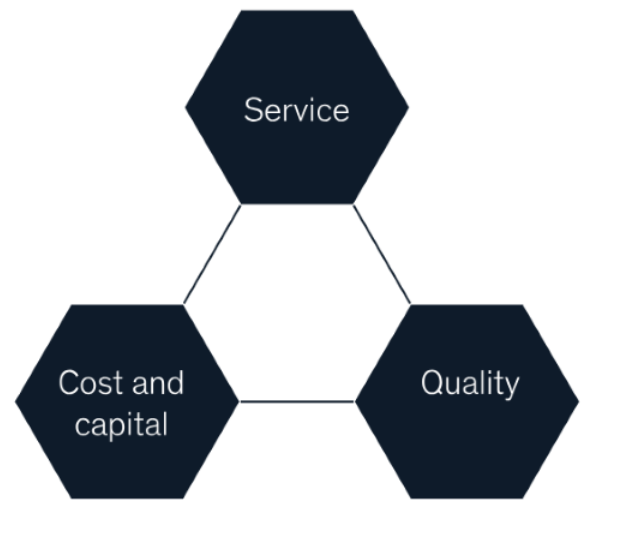

Rethinking Supply Chain Fundamentals

Where do supply chain leaders find emphasis?

In their recent study, entitled “Futureproofing the Supply Chain”, McKinsey pointed out that the entire mentality behind the balance of supply chains has changed. The traditional supply chain objectives of cost efficiency, service, and quality must now be managed with goals for resilience, agility, and sustainability.

These new priorities bring supply chains the flexibility to adapt to changes quickly and sustain through unexpected events.

This article investigates four major shifts in supply chain operation today that provide insight into what supply chains will look like near-future.

Traditional

supply chain

strategy areas

of focus

Future strategy

with new areas

of focus

source

Intelligent Automation and Machine Learning

High pressure situations encountered over recent years is causing many supply chain professionals to leave the field. According to Future of Sourcing, the supply chain talent shortage is expected to leave 2.4M positions unfilled between 2018 and 2028, creating a potential economic impact of $2.5T. At the same time, artificial intelligence is becoming more widely adopted. Many workers have begun to use AI to enhance speed and effectiveness of daily tasks. AI is still in its early stages of technology and adoption, so its impacts remain highly speculated.

With two factors combined, it is predicted that for every ten planning roles that are in the market today, only one will remain in as little as five years. Morgan Stanley goes so far as to predict that AI could take over all human touchpoints in a supply chain. On the other side of things, soon all humans will have an AI assistant to help move their jobs faster.

What does this mean for your supply chain?

The result of these changes will be very similar to the results seen with any automation increase. In addition to shifts in the day-to-day tasks of leaders in planning roles, the onset of AI means faster decision making and quicker reaction time. It also means less time built-in to assume human time structures, such as weekends, evenings, holidays, or even time needed for people to make decisions. Ultimately this change will mean supply chains are more agile to challenges, quicker, and more profitable.

Experts predict that

with the help of

machine learning

and AI, what used

to take 1000 supply

chain management

professionals could

soon take just 100.

source

Traceability

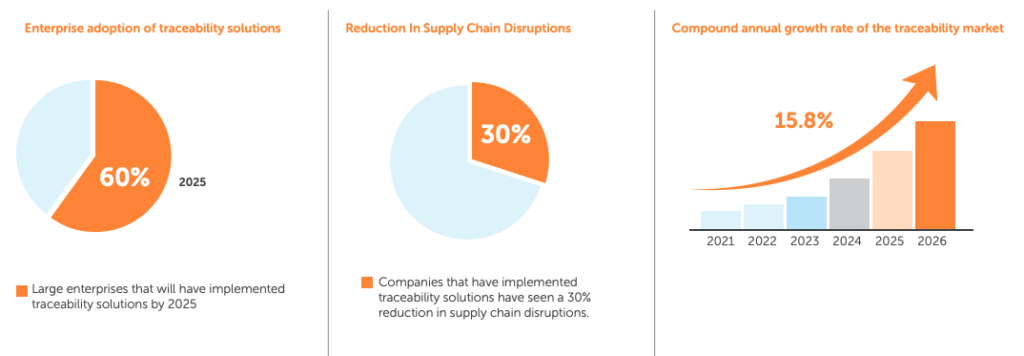

Supply chain traceability has emerged as a powerful tool in enhancing transparency, efficiency, and sustainability across supply chain networks. Regulatory shifts are a major driver for updates in traceability in today’s supply chain. For example, Section 204 of the FDA Food Safety Modernization Act compels stricter management of the cold chain, forcing stakeholders in the foodsupply chain to enhance traceability rapidly.

IoT devices, such as sensors, RFID tags, and connected devices, are playing a pivotal role in capturing real-time data throughout the supply chain. These devices enable the collection of

granular information about products, including their location, condition, temperature and handling history.

What does this mean for your supply chain?

Over the next five years, we can expect significant advancements in the integration of traceability and IoT technologies, further revolutionizing the way supply chains operate. Major advancements in battery life, infrastructure for data uploading, a reduction in tracking unit hardware pricing will play a key role in enhancing traceability.

By continuously monitoring and analyzing this data, supply chain stakeholders will proactively identify and address potential quality issues, minimizing product spoilage and ensuring

optimal quality throughout the supply chain. As a result, future supply chains will see fewer shortages, recalls and inefficiencies overall.

source

Material Shortages

According to Supply Chain Digital, the global supply chains that we know today started to kick off in the 1950s. This global reality has grown more and more prominent every year, to the point that even perishable supply chains such as meat and eggs source materials internationally. Globalization has brought about a paradigm shift in the structure and functioning of supply chains. With the advancements in transportation, communication, and technology, companies now have unprecedented opportunities to expand their operations beyond national borders.

While the prominence of globalization in supply chains can be attributed to market expansion, increased emphasis on specialization, and more, the impact of recent geopolitical events has burned some supply chain leaders, and we may start to see some elements of supply chain globalization slow down.

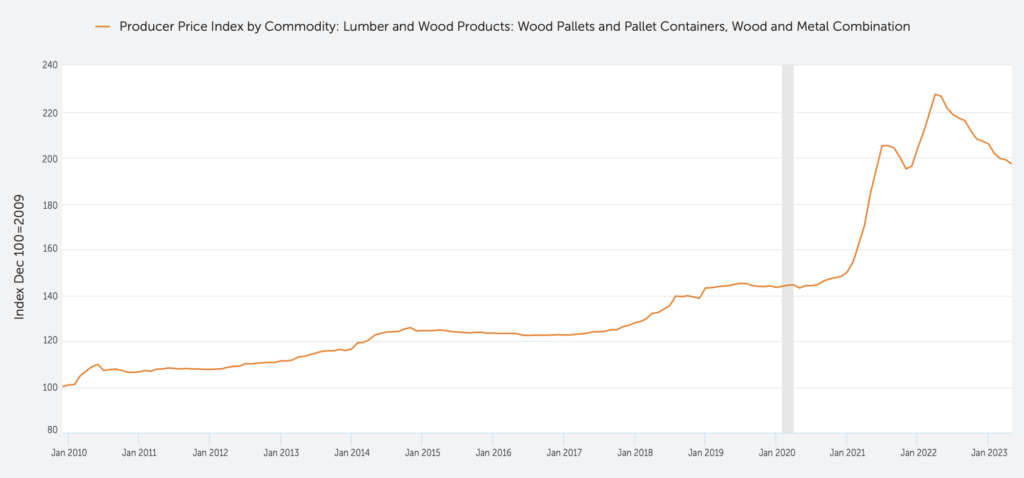

For example, the impact of the war in Ukraine and Russia has dramatically impacted the price of wood globally, an event that caused dramatic hikes in the price of wood pallets in 2021 and 2022. While the 2023 market has partially recovered from this, supply chain leaders have opened their eyes to this vulnerability. This is likely to result in supply chain leaders turning to alternatives to wood pallets that leave them less vulnerable to global sourcing issues.

source

What does this mean for your supply chain?

It is unlikely that globalization will go away entirely. Instead, supply chain leaders will build more protections into their inventory and transportation processes to reduce the impact of global catastrophes. Building flexible supply chains will become a key focus and leaders will adopt and enhance several practices to achieve that flexibility. For example, rather than risking vulnerability to geopolitical issues out of their control, future supply chain leaders are likely to maintain a larger stockpile of critical inventory. This will result in a growing need for warehouse space and smarter inventory management practices. That race toward flexibility also likely means more resources placed on reliable partners and a focus on building supply chain structures that can handle broad, unexpected shifts. Reaction time will become a critical supply chain value, and infrastructure such as machinery and essentials like pallets will need to be analyzed and reassessed for the inefficiencies the create.

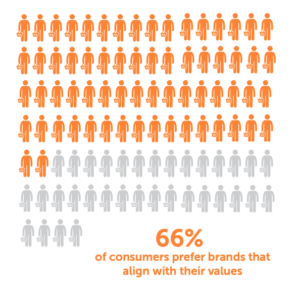

Sustainability

Sustainability and the impact your business plays on the environment is only growing more critical to consumers and other stakeholders. While not all supply chains serve consumers directly, the large retail supply chains that do are watching a population that grows more intent on sustainability and increasing the expectations they have for their third party partners. Additionally, new regulations from the SEC require companies to provide better ESG reporting to investors.

Supply chain leaders improve their capacity for a sustainable supply chain every year. KPMG recommends that supply chain leaders “Build end-to-end visibility of the supply chain to see where your goods move, the organizations that are moving them, and their sustainability credentials. With this insight, make active decisions about your partners to reduce your scope 3 total.”

What does this mean for your supply chain?

Paying attention to the sustainability efforts and ESG goals of your partners is going to play a critical role in building a supply chain that meets the standards consumers in the near future will expect. To know what your supply chain will look like in the near future, you only have to review the published sustainability goals of your customers.

For example, many customer-facing brands and retailers have committed to zero-waste goals as early as 2030. Do you bring a partnership that allows your customers to advance their

sustainability goals?

Building a supply chain for the near-future

Though many factors will impact what supply chains look like in the near future, it is already clear today that they will encompass more technology, sustainable practices, traceability and flexibility in the face of material shortages. The seeds of these changes can be seen today.

Now is the time to take steps in these known directions to allow space for the unknown. Tomorrow’s supply chain leaders are already doing it.

About Tosca

Tosca is a global leader in reusable packaging and pallet pooling solutions, delivering expert supply chain service to food supply chains all over the world. By offering a pool of reusable plastic pallets to supply chain leaders, Tosca offers a way for supply chains to access a more sustainable, more hygienic, traceable alternative to wood pallets, without needing to carry the weight of initial capital outlay and maintenance. In other words, Tosca offers supply chains tools to prepare for the near future, without the drawbacks of purchasing a pallet pool themselves.